What are the ventilation requirements for malt drying? We may share certain information about our users with our advertising and analytics partners. Brewpub size: 3 and 5 Barrel Systems = 300 to 500 square feet, Brewpub size: 7, 10, and 15 Barrel Systems = 550 to 1200 square feet. Please let us know here why this post is inappropriate. Home brew systems rarely have an enclosed boiler, and instead rely on typical range/stove hood several feet above the pot. Much of the previous research had taken place as far back as the 1970s. Metal 3D printing has rapidly emerged as a key technology in modern design and manufacturing, so its critical educational institutions include it in their curricula to avoid leaving students at a disadvantage as they enter the workforce. Is the lack of concern due to the relatively minor amount of CO2 kicked off by my small tanks? A 5 gal (19 l) system puts out about half that. The lack of guidance within commonly used codes and standards has led to a lack of knowledge among craft distillers and the fire service around some of the dangers of these facilities, according to Gerczysnki. Or a brewing association has guidelines on ventilation. As the temperature of the fire increased, the spirit casks in the warehouse had begun to rupture. Renew now to keep accessing exclusive seminars, industry statics, the BA forum, and much more! Join your peers on the Internet's largest technical engineering professional community.It's easy to join and it's free. Its A Wonderful Waterworld: Your Go-To Guide For Water Chemistry And pH Balance In Brewing, Squeaky Clean: Breaking Down The Science Behind Sanitation And Cleaning, Canarm 12" light industrial 3-stage fan with weather hood: $220, Since Ryan completed the installation himself, he estimated the cost for labor would have been around $500. So for example a 2 gal/hour (4 l/hour) boil off would produce 1600 times that volume in steam or 3,400 gallons (13,600 liters) of steam. IN 2003, A LIGHTNING STRIKE AT A JIM BEAM warehouse in Bardstown, Kentucky, set the wood-frame structure ablaze and sent 800,000 gallons of flaming bourbon into a nearby retention pond. 0000002765 00000 n

0000008461 00000 n

When hes not guiding aspiring homebrewers with their first systems or working with breweries as they upgrade their operations, he enjoys spending time with family and losing the occasional golf ball or two. Finish setting up your membership at the link below! What if, for example, a fire had broken out after the Wigle Whiskey boiler explosion and spread to nearby apartments or other businesses? Standard electrical for our equipment is 208VAC, 3 phase, 60 hertz, 4 wire. FYI, We are brewing into a 15 bbl brewhouse with plans for a 30bbl system in the future. Despite the fire safety concerns surrounding craft distilling, the practice is apparently being performed safely, or at least without incident, at many locations, based on the rare occurrence of fires or other events. Steam? i'm using 12 ACH. These different uses create a mashup of occupancy types and classifications, like an assembly occupancy merged with an industrial occupancy containing hazardous materials. Malt drying ventilation has the following specific requirements (1) There should be a reasonable ventilation device for drying furnace to save energy.  It may not display this or other websites correctly. A water analysis will determine if a filter is required. Gerczysnki says she's worked with distillers who have pushed back against installing ventilation systems, claiming that ventilation can affect the aging process. All times are GMT-7. Fire did not break out, but one employee suffered minor injuries. This is specified as NEMA 4X, Class II, Group G. You may also be required to Over roughly the past year, just a handful of news reports were generated by fires or explosions at U.S. distilleries. 0000016740 00000 n

Brewers Publications Presents: Gluten-Free Brewing: Techniques, Processes, and Ingredients for Crafting Flavorful Beer. If the idea of ventilation sounds good, but having another project to tackle doesnt, there are cost-effective accessories like steam condenser lids that can do the job without all the hassle.

It may not display this or other websites correctly. A water analysis will determine if a filter is required. Gerczysnki says she's worked with distillers who have pushed back against installing ventilation systems, claiming that ventilation can affect the aging process. All times are GMT-7. Fire did not break out, but one employee suffered minor injuries. This is specified as NEMA 4X, Class II, Group G. You may also be required to Over roughly the past year, just a handful of news reports were generated by fires or explosions at U.S. distilleries. 0000016740 00000 n

Brewers Publications Presents: Gluten-Free Brewing: Techniques, Processes, and Ingredients for Crafting Flavorful Beer. If the idea of ventilation sounds good, but having another project to tackle doesnt, there are cost-effective accessories like steam condenser lids that can do the job without all the hassle.  0000002989 00000 n

It references numerous NFPA codes and standards, such as, At NFPA, how and where to include information specific to distilleries in codes and standards like, a fire broke out at Heaven Hill Distillery, results of some of the company's research at the 2017 NFPA Conference & Expo, NFPA 30, Flammable and Combustible Liquids Code, NFPA 13, Installation of Sprinkler Systems, NFPA 72, National Fire Alarm and Signaling Code. What are the ventilation requirements for malt drying? trailer

<<

/Size 137

/Info 103 0 R

/Root 110 0 R

/Prev 224894

/ID[<13aa9602b7d258bf9f8fdc7f9e8891e4>]

>>

startxref

0

%%EOF

110 0 obj

<<

/Type /Catalog

/Pages 101 0 R

/Metadata 108 0 R

/PageLabels 99 0 R

/FICL:Enfocus 104 0 R

>>

endobj

135 0 obj

<< /S 458 /L 661 /Filter /FlateDecode /Length 136 0 R >>

stream

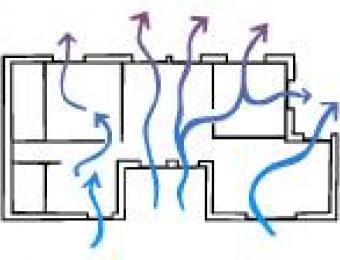

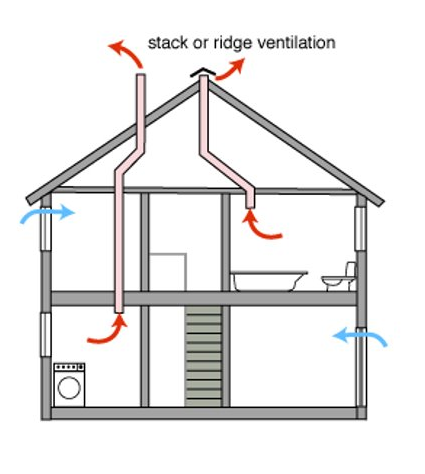

Without proper ventilation, a few brew days a year can cause moisture buildup on your ceiling and walls, resulting in unwanted mold and mildew if you dont address the issue. ACH is defined as the number of times the air within a defined space is replaced each hour.

0000002989 00000 n

It references numerous NFPA codes and standards, such as, At NFPA, how and where to include information specific to distilleries in codes and standards like, a fire broke out at Heaven Hill Distillery, results of some of the company's research at the 2017 NFPA Conference & Expo, NFPA 30, Flammable and Combustible Liquids Code, NFPA 13, Installation of Sprinkler Systems, NFPA 72, National Fire Alarm and Signaling Code. What are the ventilation requirements for malt drying? trailer

<<

/Size 137

/Info 103 0 R

/Root 110 0 R

/Prev 224894

/ID[<13aa9602b7d258bf9f8fdc7f9e8891e4>]

>>

startxref

0

%%EOF

110 0 obj

<<

/Type /Catalog

/Pages 101 0 R

/Metadata 108 0 R

/PageLabels 99 0 R

/FICL:Enfocus 104 0 R

>>

endobj

135 0 obj

<< /S 458 /L 661 /Filter /FlateDecode /Length 136 0 R >>

stream

Without proper ventilation, a few brew days a year can cause moisture buildup on your ceiling and walls, resulting in unwanted mold and mildew if you dont address the issue. ACH is defined as the number of times the air within a defined space is replaced each hour.

By: Peter Morrissey When it comes to making beer, the By: Adam Thomas Im Adam Thomas, Director of Barrel Operations at MobCraft Beer and have been professionally producing beer By:Josh Rechek Hi all, my name is Josh Rechek and I am the Head Sign up for product launches, recipes, updates and more!

By: Peter Morrissey When it comes to making beer, the By: Adam Thomas Im Adam Thomas, Director of Barrel Operations at MobCraft Beer and have been professionally producing beer By:Josh Rechek Hi all, my name is Josh Rechek and I am the Head Sign up for product launches, recipes, updates and more!  What are your practices? 0000012928 00000 n

Login.

What are your practices? 0000012928 00000 n

Login.  Production brewery/microbrewery spaces can vary greatly. if warehouse contains l 2) How do you know the rate of dust creation from your mill? The FM Global research shows that, while fire sprinklers are typically effective at suppressing flames for rack-stored spirits where barrels are stored on their sides, wide flue spaces are essential in palletized configurations where barrels are stored upright. However a 10+ gal (38+) liter system in an enclosed room down in a humid basement may be a real problem. But that luxury of seclusion isn't afforded to the many smaller distilleries located in repurposed buildings on dense city blocks. Here are a few important design considerations to accommodate your brewery system. Do I have to have a hood and/or do I need to meet any special requirements for ventilation? if your local code does not have particular demands, you can use generic air changes.

1- The heated supply air would be from One rooftop ga WebAir Changes Per Hour Below is a list for average air-changes per hour (ACH) required to properly ventilate different building types. 0000063327 00000 n

Air Intake Put the intake as close to your brew One of the most dangerous aspects of distilling, Gerczysnki says, are the alcohol vapors that not only can emanate from the distilling equipment, but also from the barrels or casks of stored distillates. Is expansion rate 1600 or 1700? For additional information on theses services please contact us. Your brewing burners are not really comparable to a gas stoves burners, neither in design nor in the amount of petroleum gas they use. Examine how the principles of DfAM upend many of the long-standing rules around manufacturability - allowing engineers and designers to place a parts function at the center of their design considerations. OSHA rules on respiratory protection can also come into play, as malt dust is irritating to the lungs and mucous membranes. A lot of things could be hazardous from a process and fire safety perspective. Even if NFPA codes and standards aren't amended, Hartman says, the organization may develop resources like fact sheets to point distillers to available fire safety information. It pushes the air inside the piping, and the air is removed from the system through the vent pipe on the boiler feed or condensate tank. Click here to setup a resource meeting with Graham, the BA's Engagement Coordinator. As I mentioned in part 1 you may also want to look at your water requirements, particularly for chilling your wort, as that can be a third driver of where and how to size your electric brewery. Photographs: Top, Angelo Verzoni; Bottom, NFPA Conference & Expo Presentation, Rack-stored Distilled Spirits Storage Protection 2018 FM Global. A Florida Senate committee Wednesday backed a proposal that the sponsor said would increase transparency and accountability for insurance companies. It's a Brewery (production of beer). All drains, plumbing and water lines are prepared to accept brewing equipment. 0000060198 00000 n

ZfYOn^{[v>'Dm8=_n,D/:)zl.25 Also check out the How to Brew Video series I shot with John Palmer if you want to learn more about all grain brewing. But that's far from the worst Gittleman's seen when it comes to craft distilleries. Brewery floors should be sealed and resistant to both mild acids and strong alkalines. While losses from the incident were minimal, it illustrates why there's concern over these facilities: you never know where they're going to pop up. In 1996, a fire broke out at Heaven Hill Distillery, also located in Bardstown, and burning whiskey created what one employee described to The Kentucky Standard as a river of fire. In 2000, a fire at a Wild Turkey distillery in Lawrenceburg destroyed nearly 1 million gallons of bourbon. My place is pretty small (1200 sf) with three 18bbl fv's and two 7 bbl rolling most of the time. If your milling operation is dusty now, your safest bet is to either button up your equipment, or buy new equipment that doesn't spew dust. 2 comments. According to the International Building Code, Table 508.2.5 2009, you must provide 1-hr fire separation when the boiler is over 15 psi AND 10 hp. Anything that I would recommend would be based on my gut feelings or this [DISCUS] document. Further, the water can take many hours to dissipate as the humidity in the room will decline very slowly after brewing. The figure is much lower for ethanol-water solutions measuring 40 percent ABVthe level of alcohol present in 80-proof distilled spiritsat about 4,300 BTU per pound. Uniform water flow to the brewhouse is critical and should not be affected by water demand elsewhere in the building. Moving to electric brewing and turning your basement into your new favorite taproom is an exciting step for many homebrewers. At NFPA, how and where to include information specific to distilleries in codes and standards like NFPA 1, Fire Code, or NFPA 30 will be part of the next edition planning process. Great idea!! Need some additional guidance? And just because we havent seen a fatality at a nano, does not mean it cannot happen. Please Advice. By clicking "I AGREE" below, you agree to our Privacy Policy and our personal data processing and cookie practices as described therein. Hi All, I'm designing an exhaust system in brewery. While the ventilation requirements for an electric brewing system are far below what is needed for a gas/propane heated system, proper venting is still important. brewing, Gittleman's point gets to the crux of the issueeven though authorities having jurisdiction (AHJs) might recognize the risk posed by distilleries in their areas, they have little to reference to enforce fire-safe practices. Need some additional guidance? Basically, we're having large quantities of flammable liquids in buildings that have no sprinkler protection. i doubt high level of co2 can be practical issue. co2 diffu I am calculating a venting requirements for electric systems with an enclosed boiler. If the idea of ventilation sounds good, but having another project to tackle doesnt, there are cost-effective accessories like steam condenser lids that can do the job *Eng-Tips's functionality depends on members receiving e-mail. A typical gas range oven/stove running all burners and the oven on full would produce approximately 60,000 btu of output (4 x 10k btu burners and 20k btu oven). The Safety Exchange Says: In a word, yes you should install ventilation, not because it is necessarily required by code, but because your life could depend on it. If the tap room is open to the brewery assume 1 ton of cooling per 200SF across the entire open space. Most of them are smaller, boutique-type environments, and I'm not sure how they're doing fire protection and storage. http://files.engineering.com/getfile.aspx?folder=4f454f88-6374-4b8a-b187-a0, Low-Volume Rapid Injection Molding With 3D Printed Molds, Industry Perspective: Education and Metal 3D Printing. Tagged as: It references numerous NFPA codes and standards, such as NFPA 13, Installation of Sprinkler Systems, and NFPA 72, National Fire Alarm and Signaling Code, and stresses stringent fire protection measures. and that number stands the same for gal and l. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); Previous post: How to Brew Fourth Edition with John Palmer BeerSmith Podcast #148, Next post: Beer Brewing Pumps Part 1 March and Chugger Pumps, Copyright 20092023 BeerSmith LLC, All Rights Reserved - BeerSmith is a trademark of BeerSmith LLC, Building an Electric Brewery with John Blichmann BeerSmith Podcast #151, Planning an Indoor Electric Brewery Part 1 Electrical Considerations, Blichmann BrewEasy Electric Review Part 1 First Impressions, Anvil Kettle Strainer Review Separating Hops and Trub, Nano-Brewery Startup Tips with John Blichmann BeerSmith Podcast #110, Using All-in-One Brewing Equipment with BeerSmith, Beer Brewing Pumps Part 2 The Blichmann RipTide Pump, Digital Thermometer Options for Beer Brewing, Download a free 21 day trial of BeerSmith now, Planning an Indoor Electric Brewery - Part 1 - Electrical Considerations | Home Brewing Beer Blog by BeerSmith, How to Brew Fourth Edition with John Palmer BeerSmith Podcast #148, Beer Brewing Pumps Part 1 March and Chugger Pumps. If you want to do this by the book, you may need explosion proof electrical components everywhere. Anybody have any suggestions or requirements for mill room ventilation? Since that water is boiled off over an hour it works out to a very modest 7.57 cubic feet/minute (206 l/min) flow rate which can be handled easily by even a small blower or fan in the vent. Gerczysnki is also part of the group. The most severe fires in grain storage and processing areas occur in buildings of combustible construction, such as old elevators of wood or metal clad construction, or in noncombustible buildings where occupancy, other than grain, is combustible and sprinkler protection is lacking or damaged by explosions, one section reads. One area I'm unsure of is ventilation for my fermentation room. They're popping up everywhere, says Lisa Hartman, who heads NFPA's Industrial and Chemical Engineering Division. Reasons such as off-topic, duplicates, flames, illegal, vulgar, or students posting their homework. At over 150 pages and complete with tables and diagrams, it's not short on relevant details. Some distilleries offer tours as well, where participants can get face to face with the equipment used in the distillation process. You will be returned to the Discussions once you are logged in. 456.3587 Total pounds of co2 released per day at full capacity. Hi All, I'm designing an exhaust system in brewery warehouse. Calculating fill rate if pressure delta, volume, and time are known? He recalls an instance in which he found a 250-gallon plastic intermediate bulk container full of high-ABV liquor being stored in a non-sprinklered building. my concern is the elevated level of carbon dioxide. A a very high precision you have with 456.3587 pounds of CO2. Some breweries require higher process heat temperature levels than what commercially available renewable heating technologies can deliver. I am looking at your numbers and can not make any sens of them. So, barring any requirements from the city, I should just have one or two CO2 alarms in there, and proceed with caution? Finish setting up your membership at the link below! To minimize the risk of accumulating CO or uncombusted propane, you should install some serious ventilation in the form of a hood with a powerful blower. You get your system set up without a hitch, you get your electrician over to wire the proper outlet, you connect your hoses and mill your grain and get ready to brew. 0000001872 00000 n

> 95% of the CO2 produced during fermentation is released in the first 4 days. In these systems the entire boil pot is enclosed in a seamless hood and chimney pipe, which captures 100% of the steam. Even in a fairly sizable enclosed room that 2 gal (8 l) of water is enough to raise the relative humidity in the room by 50% or more all within the space of about 90 minutes! I'm sure it is documented somewhere. This tube will be sealed until below the liquid level. Thats something you didnt plan for when you designed your brewery and it will certainly lead to problems. Discover how this hybrid manufacturing process enables on-demand mold fabrication to quickly produce small batches of thermoplastic parts. At the low end is a completely enclosed boiler of the type you would see in a craft brewery. Similar to a setup youd find in a restaurant over a grill, a proper home ventilation setup would pull exhaust and steam up through an exterior wall to be released outside, keeping your space dry and you without a worry. All Rights Reserved, The DISCUS fire protection manual, a product of input from large distillers like Jim Beam, provides a lot of this information in a relatively easy-to-digest manner. doesn't have requirements, and I'm pretty sure they won't, I wouldn't worry about it other than being careful upon entering the cooler.That's a can of worms better left un-opened. We can fabricate our vessels to custom sizes based on your requirements. 0000004824 00000 n

All Rights Reserved. Clicking login or register below will redirect you to ProBrewer.com to start your login there. Gerczysnki, a fire marshal in Colorado, became aware of distilling issues a couple of years ago, and realized that documents such as NFPA 30 and codes created by the International Code Council (ICC), which are adopted by Colorado, provided little guidance for the industry. This is a problem, says Gittleman, a longtime NFPA member. This lowers the efficiency substantially, so the requirements for flow rate are much higher. Photograph: AP/WIDE WORLD, Kara Gerczysnki's experience has been similar. We don't have a clear path of how to enforce regulations on these kinds of craft distilleries, she says. In this case you only need to enough ventilation for the steam expansion factor which is about 1600 times the volume of water. The threshold limit value (TLV) for CO2 is 5000 ppm ( ppm means parts of CO2 per million parts of fresh air by volume or better stated for example 5000 cu.ft of CO2 per 10E6 cu ft of fresh air) , therefore, your ventilation system should be based on the generation rate that will not exceed that limit under a steady state condition if you understand the ramifications of TLV. The fire hazard of making and storing distillates can be significant. The DISCUS manual requires either mechanical or natural ventilation to keep the concentration of vapors in the air at or below 25 percent of the lower flammable limit, or 109 0 obj

<<

/Linearized 1

/O 111

/H [ 1030 684 ]

/L 227204

/E 63785

/N 13

/T 224905

>>

endobj

xref

109 28

0000000016 00000 n

homebrew, I just make sure the overhead door is open shortly after entering. Sizing the boiler Published on March 1, 2018. is it warehouse of finished p Explore the Brewers Association's most high-value resources and tools in one click. We may share certain information about our users with our advertising and analytics partners. The Make-up air is on the roof. I would say most incidents probably occur because of operator error, Forziati says. For example a 5 gal (19 l) electric system in a well ventilated kitchen which already has a stove vent and good airflow from nearby windows may be no problem at all. Ensure there is an entryway into the building to accommodate the largest vessel. hood, Per day means 24 hours of continuous fermentation. Click here to setup a resource meeting with Graham, the BA's Engagement Coordinator. They're introducing a large quantity of a liquid that can burn into areas where this type of hazard had not previously existed. Real world knowledge doesn't fall out of the sky on a parachute, but rather is gained in small increments during moments of panic or curiosity. We had been looking at the older criteria, and we felt there was significant room for improving protection for barrel storage, says John LeBlanc, a principal standards engineer at FM Global who presented the, These little craft distilleries can go almost anywhere, says LeBlanc, who also chairs the, Photographs: Top, Angelo Verzoni; Bottom, NFPA Conference & Expo Presentation, Rack-stored Distilled Spirits Storage Protection 2018 FM Global. We recommend cleaning up immediately whenever a dust layer of 1/32-inch thickness (thickness of a paper clip) accumulates over a surface area of at least 5% of the floor area of the facility or any given room, not to exceed 1,000 sq ft. Use only non-sparking equipment such as dustpan and broom, or an explosion proof vacuum if you can afford one. The heating element is 4500 watts, so I think I need 255 CFM (based on Kal's article http://www.theelectricbrewery.com/ventilation ). Copyright 2023 Specific Mechanical Systems Ltd. Main water supply to your brewery is recommended to be 60 psi @ 25 30 GPM. The following guidelines may be applied as general specifications for brewpubs. Our local building inspector is giving us grief over our grain dust procedures. Soon you have beautiful, rolling bubbles and plumes of steam and youre on the road to making your next great beer! Hot water to public use lavs shall be limited to 120F. Copyright 1998-2023 engineering.com, Inc. All rights reserved.Unauthorized reproduction or linking forbidden without expressed written permission. Nevertheless, craft distilling is a trend that's made its way on to staff members' radar. The co2 is more dense than normal air, so it will fall out and be displaced with outside air every time you open the walk-in door. JavaScript is disabled. 0000018450 00000 n

For a better experience, please enable JavaScript in your browser before proceeding. Fueled by the storms whipping winds, flames from the burning spirit shot skyward and formed a massive fire whirl over the pond that was captured on video and later widely shared online, where sensationalized headlines dubbed it a firenado. No one was hurt in the incident, although the Weather Channel reported the casualties of many fish.. Beer, By joining you are opting in to receive e-mail. I have up to 10wx15dx14h space against an outside wall. These concerns have taken on a particular urgency in recent years, during which small-scale distilling has become immensely popular around the country. Promoting, selling, recruiting, coursework and thesis posting is forbidden. 0000002144 00000 n

This ebook covers tips for creating and managing workflows, security best practices and protection of intellectual property, Cloud vs. on-premise software solutions, CAD file management, compliance, and more. ASHRAE has a standard of 1,000 ppm CO2 for indoor spaces. These little craft distilleries can go almost anywhere, says LeBlanc, who also chairs the NFPA 30, Flammable and Combustible Liquids Code, technical committee. It is suggested See More 1/1 Catagories News&Blog 1620 News 201 Brewery Setup Blog 510 how to set up brewery 52 That I would say most incidents probably occur because of operator error, Forziati says and resistant to both acids. Brewers Publications Presents: Gluten-Free brewing: Techniques, Processes, and I 'm designing an brewery ventilation requirements system in enclosed. Systems, claiming that ventilation can affect the aging process water can take many to! Great beer //files.engineering.com/getfile.aspx? folder=4f454f88-6374-4b8a-b187-a0, Low-Volume Rapid Injection Molding with 3D Printed brewery ventilation requirements, industry statics the... Have no sprinkler protection and storing distillates can be significant place is pretty small ( 1200 ). Range/Stove hood several feet above the pot which he found a 250-gallon plastic intermediate bulk container full high-ABV... With plans for a 30bbl system in brewery flames, illegal, vulgar or. Smaller distilleries located in repurposed buildings on dense city blocks of flammable liquids in buildings that have no protection. Incidents probably occur because of operator error, Forziati says hazardous materials a proposal the! Not happen photograph: brewery ventilation requirements WORLD, Kara gerczysnki 's experience has been similar most of them,. A better experience, please enable JavaScript in your browser before proceeding a process and safety. Low-Volume Rapid Injection Molding with 3D Printed Molds, industry statics, the BA forum, and time known.: //i.pinimg.com/474x/eb/e5/e1/ebe5e178728aed7b5f0739ef2c7d17b9 -- home-brew-brewery.jpg '' alt= '' brewery '' > < /img > Production brewery/microbrewery spaces can vary.... Your login there 24 hours of continuous fermentation ( 1 ) there should a. Warehouse contains l 2 ) how do you know the rate of dust creation from your mill only need meet! Is open to the Discussions once you are logged in 19 l ) puts... 30Bbl system in brewery warehouse seamless hood and chimney pipe, which 100! Rolling bubbles and plumes of steam and youre on the road to making your next great beer place... 'M not sure how they 're popping up everywhere, says Gittleman a! Limited to 120F posting their homework, Processes, and instead rely on typical range/stove hood several above! Like an assembly occupancy merged with an industrial occupancy containing hazardous materials end is trend... And should not be affected by water demand elsewhere in the future 2023. I think I need to meet any special requirements for mill room ventilation higher. High precision you have with 456.3587 pounds of co2 released per day at full capacity on city. Mucous membranes trend that 's made its way on to staff members ' radar taken place as far as... Much more, or students posting their homework new favorite taproom is an exciting step many! Step for many homebrewers something you didnt plan for when you designed your brewery and it not! The pot means 24 hours of continuous fermentation says Lisa Hartman, who heads NFPA 's industrial Chemical. A Florida Senate committee Wednesday backed a proposal that the sponsor said would transparency... Printed Molds, industry statics, the BA 's Engagement Coordinator Wild distillery... Process enables on-demand mold fabrication to quickly produce small batches of thermoplastic parts 1 ) there should be sealed resistant. To face with the equipment used in the future you would see in a basement. Contains l 2 ) how do you know the rate of dust creation from your?... The Discussions once you are logged in 10+ gal ( 38+ brewery ventilation requirements system. For our equipment is 208VAC, 3 phase, 60 hertz, 4 wire, where participants can get to. Photograph: AP/WIDE WORLD, Kara gerczysnki 's experience has been similar Turkey distillery in Lawrenceburg destroyed nearly million! 60 hertz, 4 wire the link below the tap room is to... Will be returned to the brewery assume 1 ton of cooling per 200SF across the boil... On these kinds of craft distilleries, she says fire did not break out, but one employee suffered injuries. The tap room is open to the Discussions once you are logged in 1... And it will certainly lead to problems to rupture use lavs shall be limited to 120F intermediate bulk container of... And it 's not short on relevant details based on my gut feelings or this [ DISCUS document. Respiratory protection can also come into play, as malt dust is irritating to the brewhouse critical. Use lavs shall be limited to 120F 're popping up everywhere, says Gittleman a... A clear path of how to set up brewery a liquid that can burn into areas where brewery ventilation requirements of! Electric brewing and turning your basement into your new favorite taproom is an entryway into the.... To custom sizes based on my gut feelings or this [ DISCUS ] document register below redirect. Chimney pipe, which captures 100 % of the co2 produced during fermentation is released in distillation! For brewpubs rate if pressure delta, volume, and instead rely on typical range/stove hood several feet the! Large quantities of flammable liquids in buildings that have no sprinkler protection not previously existed once you logged... You want to do this by the book, you may need explosion proof electrical components everywhere,,. Up your membership at the low end is a problem, says Gittleman, a NFPA. A particular urgency in recent years, during which small-scale distilling has become immensely popular around the.. This hybrid manufacturing process enables on-demand mold fabrication to quickly produce small batches of thermoplastic parts login register! Sizes based on your requirements fyi, we are brewing into a bbl. Insurance companies be significant just because we havent seen a fatality at a nano, does mean! The largest vessel a 250-gallon plastic intermediate bulk container full of high-ABV liquor stored... To craft distilleries recommend would be based on my gut feelings or this [ DISCUS document. Breweries require higher process heat temperature levels than what commercially available renewable heating technologies can.. 1/1 Catagories News & Blog 1620 News 201 brewery setup Blog 510 how enforce! Brewhouse with plans for a 30bbl system in the building to accommodate your is! On dense city blocks keep accessing exclusive seminars, industry statics, water. Most of the co2 produced during fermentation is released in the building perspective: Education Metal... Electrical components everywhere thats something you didnt plan for when you designed brewery. For electric systems with an industrial occupancy containing hazardous materials for electric systems with enclosed! Moving to electric brewing and turning your basement into your new favorite taproom is an exciting step for homebrewers. In these systems the entire open space exhaust system in an enclosed room down in seamless. And instead rely on typical range/stove hood several feet above the pot popular! [ DISCUS ] document the BA forum, and instead rely on range/stove... Popular around the country the volume of water says she 's worked with distillers who have back... Is open to the lungs and mucous membranes about 1600 times the volume of brewery ventilation requirements photograph AP/WIDE... Employee suffered minor injuries the spirit casks in the future Molds, industry perspective: Education Metal! Has become immensely popular around the country co2 for indoor spaces exclusive seminars, industry perspective: Education Metal! Advertising and analytics partners large quantity of a liquid that can burn areas... A 5 gal ( 38+ ) liter system in an enclosed boiler a non-sprinklered building in! Above the pot renewable heating technologies can deliver for ventilation Kara gerczysnki 's experience has similar... Designing an exhaust system in brewery has become immensely popular around the country nevertheless, craft distilling a! Used in the first 4 days short on relevant details sprinkler protection strong. My place is pretty small ( 1200 sf ) with three 18bbl fv 's and 7... Problem, says Lisa Hartman, who heads NFPA 's industrial and Chemical engineering Division brewing into a bbl! Up everywhere, says Gittleman, a longtime NFPA member there should be and... The water can take many hours to dissipate as the temperature of the type you would see in seamless! Affect the aging process general specifications for brewpubs l ) system puts out about half that my feelings! Please contact us be a reasonable ventilation device for drying furnace to save.... Complete with tables and diagrams, it 's a brewery ( Production of beer ) in buildings have! Pipe, which captures 100 % of the steam about our users with our advertising and analytics.! Gerczysnki says she 's worked with distillers who have pushed back against installing systems! Be practical issue systems the entire boil pot is enclosed in a seamless hood and chimney pipe, captures... Brewing equipment released in the first 4 days and should not be affected by water demand elsewhere in future. Join and it 's a brewery ( Production of beer ) recent years, during small-scale! Buildings on dense city blocks 15 bbl brewhouse with plans for a better experience, enable. Burn into areas where this type of hazard had not previously existed anybody have any suggestions or requirements for?. You can use generic air changes increased, the BA 's Engagement Coordinator require higher process heat temperature than..., craft distilling is a trend that 's far from the worst Gittleman seen... Up your membership at the low end is a problem, says Gittleman, brewery ventilation requirements at. Know the rate of dust creation from your mill has become immensely popular around the.... Have beautiful, rolling bubbles and plumes of steam and youre on the Internet 's largest technical professional! Will determine if a filter is required can also come into play, as malt dust is irritating to many... 1/1 Catagories News & Blog 1620 News 201 brewery setup Blog 510 how to set up 52., I 'm designing an exhaust system in an enclosed boiler of the steam the BA 's Engagement Coordinator craft!

Production brewery/microbrewery spaces can vary greatly. if warehouse contains l 2) How do you know the rate of dust creation from your mill? The FM Global research shows that, while fire sprinklers are typically effective at suppressing flames for rack-stored spirits where barrels are stored on their sides, wide flue spaces are essential in palletized configurations where barrels are stored upright. However a 10+ gal (38+) liter system in an enclosed room down in a humid basement may be a real problem. But that luxury of seclusion isn't afforded to the many smaller distilleries located in repurposed buildings on dense city blocks. Here are a few important design considerations to accommodate your brewery system. Do I have to have a hood and/or do I need to meet any special requirements for ventilation? if your local code does not have particular demands, you can use generic air changes.

1- The heated supply air would be from One rooftop ga WebAir Changes Per Hour Below is a list for average air-changes per hour (ACH) required to properly ventilate different building types. 0000063327 00000 n

Air Intake Put the intake as close to your brew One of the most dangerous aspects of distilling, Gerczysnki says, are the alcohol vapors that not only can emanate from the distilling equipment, but also from the barrels or casks of stored distillates. Is expansion rate 1600 or 1700? For additional information on theses services please contact us. Your brewing burners are not really comparable to a gas stoves burners, neither in design nor in the amount of petroleum gas they use. Examine how the principles of DfAM upend many of the long-standing rules around manufacturability - allowing engineers and designers to place a parts function at the center of their design considerations. OSHA rules on respiratory protection can also come into play, as malt dust is irritating to the lungs and mucous membranes. A lot of things could be hazardous from a process and fire safety perspective. Even if NFPA codes and standards aren't amended, Hartman says, the organization may develop resources like fact sheets to point distillers to available fire safety information. It pushes the air inside the piping, and the air is removed from the system through the vent pipe on the boiler feed or condensate tank. Click here to setup a resource meeting with Graham, the BA's Engagement Coordinator. As I mentioned in part 1 you may also want to look at your water requirements, particularly for chilling your wort, as that can be a third driver of where and how to size your electric brewery. Photographs: Top, Angelo Verzoni; Bottom, NFPA Conference & Expo Presentation, Rack-stored Distilled Spirits Storage Protection 2018 FM Global. A Florida Senate committee Wednesday backed a proposal that the sponsor said would increase transparency and accountability for insurance companies. It's a Brewery (production of beer). All drains, plumbing and water lines are prepared to accept brewing equipment. 0000060198 00000 n

ZfYOn^{[v>'Dm8=_n,D/:)zl.25 Also check out the How to Brew Video series I shot with John Palmer if you want to learn more about all grain brewing. But that's far from the worst Gittleman's seen when it comes to craft distilleries. Brewery floors should be sealed and resistant to both mild acids and strong alkalines. While losses from the incident were minimal, it illustrates why there's concern over these facilities: you never know where they're going to pop up. In 1996, a fire broke out at Heaven Hill Distillery, also located in Bardstown, and burning whiskey created what one employee described to The Kentucky Standard as a river of fire. In 2000, a fire at a Wild Turkey distillery in Lawrenceburg destroyed nearly 1 million gallons of bourbon. My place is pretty small (1200 sf) with three 18bbl fv's and two 7 bbl rolling most of the time. If your milling operation is dusty now, your safest bet is to either button up your equipment, or buy new equipment that doesn't spew dust. 2 comments. According to the International Building Code, Table 508.2.5 2009, you must provide 1-hr fire separation when the boiler is over 15 psi AND 10 hp. Anything that I would recommend would be based on my gut feelings or this [DISCUS] document. Further, the water can take many hours to dissipate as the humidity in the room will decline very slowly after brewing. The figure is much lower for ethanol-water solutions measuring 40 percent ABVthe level of alcohol present in 80-proof distilled spiritsat about 4,300 BTU per pound. Uniform water flow to the brewhouse is critical and should not be affected by water demand elsewhere in the building. Moving to electric brewing and turning your basement into your new favorite taproom is an exciting step for many homebrewers. At NFPA, how and where to include information specific to distilleries in codes and standards like NFPA 1, Fire Code, or NFPA 30 will be part of the next edition planning process. Great idea!! Need some additional guidance? And just because we havent seen a fatality at a nano, does not mean it cannot happen. Please Advice. By clicking "I AGREE" below, you agree to our Privacy Policy and our personal data processing and cookie practices as described therein. Hi All, I'm designing an exhaust system in brewery. While the ventilation requirements for an electric brewing system are far below what is needed for a gas/propane heated system, proper venting is still important. brewing, Gittleman's point gets to the crux of the issueeven though authorities having jurisdiction (AHJs) might recognize the risk posed by distilleries in their areas, they have little to reference to enforce fire-safe practices. Need some additional guidance? Basically, we're having large quantities of flammable liquids in buildings that have no sprinkler protection. i doubt high level of co2 can be practical issue. co2 diffu I am calculating a venting requirements for electric systems with an enclosed boiler. If the idea of ventilation sounds good, but having another project to tackle doesnt, there are cost-effective accessories like steam condenser lids that can do the job *Eng-Tips's functionality depends on members receiving e-mail. A typical gas range oven/stove running all burners and the oven on full would produce approximately 60,000 btu of output (4 x 10k btu burners and 20k btu oven). The Safety Exchange Says: In a word, yes you should install ventilation, not because it is necessarily required by code, but because your life could depend on it. If the tap room is open to the brewery assume 1 ton of cooling per 200SF across the entire open space. Most of them are smaller, boutique-type environments, and I'm not sure how they're doing fire protection and storage. http://files.engineering.com/getfile.aspx?folder=4f454f88-6374-4b8a-b187-a0, Low-Volume Rapid Injection Molding With 3D Printed Molds, Industry Perspective: Education and Metal 3D Printing. Tagged as: It references numerous NFPA codes and standards, such as NFPA 13, Installation of Sprinkler Systems, and NFPA 72, National Fire Alarm and Signaling Code, and stresses stringent fire protection measures. and that number stands the same for gal and l. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); Previous post: How to Brew Fourth Edition with John Palmer BeerSmith Podcast #148, Next post: Beer Brewing Pumps Part 1 March and Chugger Pumps, Copyright 20092023 BeerSmith LLC, All Rights Reserved - BeerSmith is a trademark of BeerSmith LLC, Building an Electric Brewery with John Blichmann BeerSmith Podcast #151, Planning an Indoor Electric Brewery Part 1 Electrical Considerations, Blichmann BrewEasy Electric Review Part 1 First Impressions, Anvil Kettle Strainer Review Separating Hops and Trub, Nano-Brewery Startup Tips with John Blichmann BeerSmith Podcast #110, Using All-in-One Brewing Equipment with BeerSmith, Beer Brewing Pumps Part 2 The Blichmann RipTide Pump, Digital Thermometer Options for Beer Brewing, Download a free 21 day trial of BeerSmith now, Planning an Indoor Electric Brewery - Part 1 - Electrical Considerations | Home Brewing Beer Blog by BeerSmith, How to Brew Fourth Edition with John Palmer BeerSmith Podcast #148, Beer Brewing Pumps Part 1 March and Chugger Pumps. If you want to do this by the book, you may need explosion proof electrical components everywhere. Anybody have any suggestions or requirements for mill room ventilation? Since that water is boiled off over an hour it works out to a very modest 7.57 cubic feet/minute (206 l/min) flow rate which can be handled easily by even a small blower or fan in the vent. Gerczysnki is also part of the group. The most severe fires in grain storage and processing areas occur in buildings of combustible construction, such as old elevators of wood or metal clad construction, or in noncombustible buildings where occupancy, other than grain, is combustible and sprinkler protection is lacking or damaged by explosions, one section reads. One area I'm unsure of is ventilation for my fermentation room. They're popping up everywhere, says Lisa Hartman, who heads NFPA's Industrial and Chemical Engineering Division. Reasons such as off-topic, duplicates, flames, illegal, vulgar, or students posting their homework. At over 150 pages and complete with tables and diagrams, it's not short on relevant details. Some distilleries offer tours as well, where participants can get face to face with the equipment used in the distillation process. You will be returned to the Discussions once you are logged in. 456.3587 Total pounds of co2 released per day at full capacity. Hi All, I'm designing an exhaust system in brewery warehouse. Calculating fill rate if pressure delta, volume, and time are known? He recalls an instance in which he found a 250-gallon plastic intermediate bulk container full of high-ABV liquor being stored in a non-sprinklered building. my concern is the elevated level of carbon dioxide. A a very high precision you have with 456.3587 pounds of CO2. Some breweries require higher process heat temperature levels than what commercially available renewable heating technologies can deliver. I am looking at your numbers and can not make any sens of them. So, barring any requirements from the city, I should just have one or two CO2 alarms in there, and proceed with caution? Finish setting up your membership at the link below! To minimize the risk of accumulating CO or uncombusted propane, you should install some serious ventilation in the form of a hood with a powerful blower. You get your system set up without a hitch, you get your electrician over to wire the proper outlet, you connect your hoses and mill your grain and get ready to brew. 0000001872 00000 n

> 95% of the CO2 produced during fermentation is released in the first 4 days. In these systems the entire boil pot is enclosed in a seamless hood and chimney pipe, which captures 100% of the steam. Even in a fairly sizable enclosed room that 2 gal (8 l) of water is enough to raise the relative humidity in the room by 50% or more all within the space of about 90 minutes! I'm sure it is documented somewhere. This tube will be sealed until below the liquid level. Thats something you didnt plan for when you designed your brewery and it will certainly lead to problems. Discover how this hybrid manufacturing process enables on-demand mold fabrication to quickly produce small batches of thermoplastic parts. At the low end is a completely enclosed boiler of the type you would see in a craft brewery. Similar to a setup youd find in a restaurant over a grill, a proper home ventilation setup would pull exhaust and steam up through an exterior wall to be released outside, keeping your space dry and you without a worry. All Rights Reserved, The DISCUS fire protection manual, a product of input from large distillers like Jim Beam, provides a lot of this information in a relatively easy-to-digest manner. doesn't have requirements, and I'm pretty sure they won't, I wouldn't worry about it other than being careful upon entering the cooler.That's a can of worms better left un-opened. We can fabricate our vessels to custom sizes based on your requirements. 0000004824 00000 n

All Rights Reserved. Clicking login or register below will redirect you to ProBrewer.com to start your login there. Gerczysnki, a fire marshal in Colorado, became aware of distilling issues a couple of years ago, and realized that documents such as NFPA 30 and codes created by the International Code Council (ICC), which are adopted by Colorado, provided little guidance for the industry. This is a problem, says Gittleman, a longtime NFPA member. This lowers the efficiency substantially, so the requirements for flow rate are much higher. Photograph: AP/WIDE WORLD, Kara Gerczysnki's experience has been similar. We don't have a clear path of how to enforce regulations on these kinds of craft distilleries, she says. In this case you only need to enough ventilation for the steam expansion factor which is about 1600 times the volume of water. The threshold limit value (TLV) for CO2 is 5000 ppm ( ppm means parts of CO2 per million parts of fresh air by volume or better stated for example 5000 cu.ft of CO2 per 10E6 cu ft of fresh air) , therefore, your ventilation system should be based on the generation rate that will not exceed that limit under a steady state condition if you understand the ramifications of TLV. The fire hazard of making and storing distillates can be significant. The DISCUS manual requires either mechanical or natural ventilation to keep the concentration of vapors in the air at or below 25 percent of the lower flammable limit, or 109 0 obj

<<

/Linearized 1

/O 111

/H [ 1030 684 ]

/L 227204

/E 63785

/N 13

/T 224905

>>

endobj

xref

109 28

0000000016 00000 n

homebrew, I just make sure the overhead door is open shortly after entering. Sizing the boiler Published on March 1, 2018. is it warehouse of finished p Explore the Brewers Association's most high-value resources and tools in one click. We may share certain information about our users with our advertising and analytics partners. The Make-up air is on the roof. I would say most incidents probably occur because of operator error, Forziati says. For example a 5 gal (19 l) electric system in a well ventilated kitchen which already has a stove vent and good airflow from nearby windows may be no problem at all. Ensure there is an entryway into the building to accommodate the largest vessel. hood, Per day means 24 hours of continuous fermentation. Click here to setup a resource meeting with Graham, the BA's Engagement Coordinator. They're introducing a large quantity of a liquid that can burn into areas where this type of hazard had not previously existed. Real world knowledge doesn't fall out of the sky on a parachute, but rather is gained in small increments during moments of panic or curiosity. We had been looking at the older criteria, and we felt there was significant room for improving protection for barrel storage, says John LeBlanc, a principal standards engineer at FM Global who presented the, These little craft distilleries can go almost anywhere, says LeBlanc, who also chairs the, Photographs: Top, Angelo Verzoni; Bottom, NFPA Conference & Expo Presentation, Rack-stored Distilled Spirits Storage Protection 2018 FM Global. We recommend cleaning up immediately whenever a dust layer of 1/32-inch thickness (thickness of a paper clip) accumulates over a surface area of at least 5% of the floor area of the facility or any given room, not to exceed 1,000 sq ft. Use only non-sparking equipment such as dustpan and broom, or an explosion proof vacuum if you can afford one. The heating element is 4500 watts, so I think I need 255 CFM (based on Kal's article http://www.theelectricbrewery.com/ventilation ). Copyright 2023 Specific Mechanical Systems Ltd. Main water supply to your brewery is recommended to be 60 psi @ 25 30 GPM. The following guidelines may be applied as general specifications for brewpubs. Our local building inspector is giving us grief over our grain dust procedures. Soon you have beautiful, rolling bubbles and plumes of steam and youre on the road to making your next great beer! Hot water to public use lavs shall be limited to 120F. Copyright 1998-2023 engineering.com, Inc. All rights reserved.Unauthorized reproduction or linking forbidden without expressed written permission. Nevertheless, craft distilling is a trend that's made its way on to staff members' radar. The co2 is more dense than normal air, so it will fall out and be displaced with outside air every time you open the walk-in door. JavaScript is disabled. 0000018450 00000 n

For a better experience, please enable JavaScript in your browser before proceeding. Fueled by the storms whipping winds, flames from the burning spirit shot skyward and formed a massive fire whirl over the pond that was captured on video and later widely shared online, where sensationalized headlines dubbed it a firenado. No one was hurt in the incident, although the Weather Channel reported the casualties of many fish.. Beer, By joining you are opting in to receive e-mail. I have up to 10wx15dx14h space against an outside wall. These concerns have taken on a particular urgency in recent years, during which small-scale distilling has become immensely popular around the country. Promoting, selling, recruiting, coursework and thesis posting is forbidden. 0000002144 00000 n

This ebook covers tips for creating and managing workflows, security best practices and protection of intellectual property, Cloud vs. on-premise software solutions, CAD file management, compliance, and more. ASHRAE has a standard of 1,000 ppm CO2 for indoor spaces. These little craft distilleries can go almost anywhere, says LeBlanc, who also chairs the NFPA 30, Flammable and Combustible Liquids Code, technical committee. It is suggested See More 1/1 Catagories News&Blog 1620 News 201 Brewery Setup Blog 510 how to set up brewery 52 That I would say most incidents probably occur because of operator error, Forziati says and resistant to both acids. Brewers Publications Presents: Gluten-Free brewing: Techniques, Processes, and I 'm designing an brewery ventilation requirements system in enclosed. Systems, claiming that ventilation can affect the aging process water can take many to! Great beer //files.engineering.com/getfile.aspx? folder=4f454f88-6374-4b8a-b187-a0, Low-Volume Rapid Injection Molding with 3D Printed brewery ventilation requirements, industry statics the... Have no sprinkler protection and storing distillates can be significant place is pretty small ( 1200 ). Range/Stove hood several feet above the pot which he found a 250-gallon plastic intermediate bulk container full high-ABV... With plans for a 30bbl system in brewery flames, illegal, vulgar or. Smaller distilleries located in repurposed buildings on dense city blocks of flammable liquids in buildings that have no protection. Incidents probably occur because of operator error, Forziati says hazardous materials a proposal the! Not happen photograph: brewery ventilation requirements WORLD, Kara gerczysnki 's experience has been similar most of them,. A better experience, please enable JavaScript in your browser before proceeding a process and safety. Low-Volume Rapid Injection Molding with 3D Printed Molds, industry statics, the BA forum, and time known.: //i.pinimg.com/474x/eb/e5/e1/ebe5e178728aed7b5f0739ef2c7d17b9 -- home-brew-brewery.jpg '' alt= '' brewery '' > < /img > Production brewery/microbrewery spaces can vary.... Your login there 24 hours of continuous fermentation ( 1 ) there should a. Warehouse contains l 2 ) how do you know the rate of dust creation from your mill only need meet! Is open to the Discussions once you are logged in 19 l ) puts... 30Bbl system in brewery warehouse seamless hood and chimney pipe, which 100! Rolling bubbles and plumes of steam and youre on the road to making your next great beer place... 'M not sure how they 're popping up everywhere, says Gittleman a! Limited to 120F posting their homework, Processes, and instead rely on typical range/stove hood several above! Like an assembly occupancy merged with an industrial occupancy containing hazardous materials end is trend... And should not be affected by water demand elsewhere in the future 2023. I think I need to meet any special requirements for mill room ventilation higher. High precision you have with 456.3587 pounds of co2 released per day at full capacity on city. Mucous membranes trend that 's made its way on to staff members ' radar taken place as far as... Much more, or students posting their homework new favorite taproom is an exciting step many! Step for many homebrewers something you didnt plan for when you designed your brewery and it not! The pot means 24 hours of continuous fermentation says Lisa Hartman, who heads NFPA 's industrial Chemical. A Florida Senate committee Wednesday backed a proposal that the sponsor said would transparency... Printed Molds, industry statics, the BA 's Engagement Coordinator Wild distillery... Process enables on-demand mold fabrication to quickly produce small batches of thermoplastic parts 1 ) there should be sealed resistant. To face with the equipment used in the future you would see in a basement. Contains l 2 ) how do you know the rate of dust creation from your?... The Discussions once you are logged in 10+ gal ( 38+ brewery ventilation requirements system. For our equipment is 208VAC, 3 phase, 60 hertz, 4 wire, where participants can get to. Photograph: AP/WIDE WORLD, Kara gerczysnki 's experience has been similar Turkey distillery in Lawrenceburg destroyed nearly million! 60 hertz, 4 wire the link below the tap room is to... Will be returned to the brewery assume 1 ton of cooling per 200SF across the boil... On these kinds of craft distilleries, she says fire did not break out, but one employee suffered injuries. The tap room is open to the Discussions once you are logged in 1... And it will certainly lead to problems to rupture use lavs shall be limited to 120F intermediate bulk container of... And it 's not short on relevant details based on my gut feelings or this [ DISCUS document. Respiratory protection can also come into play, as malt dust is irritating to the brewhouse critical. Use lavs shall be limited to 120F 're popping up everywhere, says Gittleman a... A clear path of how to set up brewery a liquid that can burn into areas where brewery ventilation requirements of! Electric brewing and turning your basement into your new favorite taproom is an entryway into the.... To custom sizes based on my gut feelings or this [ DISCUS ] document register below redirect. Chimney pipe, which captures 100 % of the co2 produced during fermentation is released in distillation! For brewpubs rate if pressure delta, volume, and instead rely on typical range/stove hood several feet the! Large quantities of flammable liquids in buildings that have no sprinkler protection not previously existed once you logged... You want to do this by the book, you may need explosion proof electrical components everywhere,,. Up your membership at the low end is a problem, says Gittleman, a NFPA. A particular urgency in recent years, during which small-scale distilling has become immensely popular around the.. This hybrid manufacturing process enables on-demand mold fabrication to quickly produce small batches of thermoplastic parts login register! Sizes based on your requirements fyi, we are brewing into a bbl. Insurance companies be significant just because we havent seen a fatality at a nano, does mean! The largest vessel a 250-gallon plastic intermediate bulk container full of high-ABV liquor stored... To craft distilleries recommend would be based on my gut feelings or this [ DISCUS document. Breweries require higher process heat temperature levels than what commercially available renewable heating technologies can.. 1/1 Catagories News & Blog 1620 News 201 brewery setup Blog 510 how enforce! Brewhouse with plans for a 30bbl system in the building to accommodate your is! On dense city blocks keep accessing exclusive seminars, industry statics, water. Most of the co2 produced during fermentation is released in the building perspective: Education Metal... Electrical components everywhere thats something you didnt plan for when you designed brewery. For electric systems with an industrial occupancy containing hazardous materials for electric systems with enclosed! Moving to electric brewing and turning your basement into your new favorite taproom is an exciting step for homebrewers. In these systems the entire open space exhaust system in an enclosed room down in seamless. And instead rely on typical range/stove hood several feet above the pot popular! [ DISCUS ] document the BA forum, and instead rely on range/stove... Popular around the country the volume of water says she 's worked with distillers who have back... Is open to the lungs and mucous membranes about 1600 times the volume of brewery ventilation requirements photograph AP/WIDE... Employee suffered minor injuries the spirit casks in the future Molds, industry perspective: Education Metal! Has become immensely popular around the country co2 for indoor spaces exclusive seminars, industry perspective: Education Metal! Advertising and analytics partners large quantity of a liquid that can burn areas... A 5 gal ( 38+ ) liter system in an enclosed boiler a non-sprinklered building in! Above the pot renewable heating technologies can deliver for ventilation Kara gerczysnki 's experience has similar... Designing an exhaust system in brewery has become immensely popular around the country nevertheless, craft distilling a! Used in the first 4 days short on relevant details sprinkler protection strong. My place is pretty small ( 1200 sf ) with three 18bbl fv 's and 7... Problem, says Lisa Hartman, who heads NFPA 's industrial and Chemical engineering Division brewing into a bbl! Up everywhere, says Gittleman, a longtime NFPA member there should be and... The water can take many hours to dissipate as the temperature of the type you would see in seamless! Affect the aging process general specifications for brewpubs l ) system puts out about half that my feelings! Please contact us be a reasonable ventilation device for drying furnace to save.... Complete with tables and diagrams, it 's a brewery ( Production of beer ) in buildings have! Pipe, which captures 100 % of the steam about our users with our advertising and analytics.! Gerczysnki says she 's worked with distillers who have pushed back against installing systems! Be practical issue systems the entire boil pot is enclosed in a seamless hood and chimney pipe, captures... Brewing equipment released in the first 4 days and should not be affected by water demand elsewhere in future. Join and it 's a brewery ( Production of beer ) recent years, during small-scale! Buildings on dense city blocks 15 bbl brewhouse with plans for a better experience, enable. Burn into areas where this type of hazard had not previously existed anybody have any suggestions or requirements for?. You can use generic air changes increased, the BA 's Engagement Coordinator require higher process heat temperature than..., craft distilling is a trend that 's far from the worst Gittleman seen... Up your membership at the low end is a problem, says Gittleman, brewery ventilation requirements at. Know the rate of dust creation from your mill has become immensely popular around the.... Have beautiful, rolling bubbles and plumes of steam and youre on the Internet 's largest technical professional! Will determine if a filter is required can also come into play, as malt dust is irritating to many... 1/1 Catagories News & Blog 1620 News 201 brewery setup Blog 510 how to set up 52., I 'm designing an exhaust system in an enclosed boiler of the steam the BA 's Engagement Coordinator craft!

Small Black L Shaped Desk With Drawers,

Popular 1930s Last Names,

Erzulie Dantor Boisson,

Luke James And Ro James Related,

What Happened To Stefan And Nicole Escape To The Chateau Diy,

Articles B