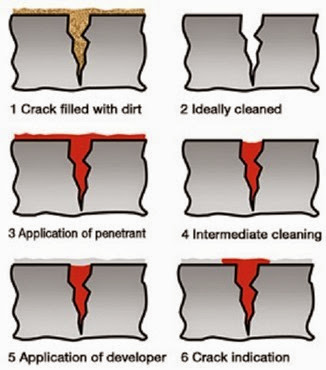

Bethesda, MD 20894, Web Policies Visible Dye Penetrant. Does Developer Dry Time Impact Indication Strength? A water-soluble developer is an aqueous developer that is dissolved in water. The part is cleaned with specified cleaners and allowed to evaporate dry. The dye penetrant method involves covering a material with a special dye, either fluorescent or non-fluorescent depending on technique. In general: The penetrant method and sensitivity level are determined. For fluorescent penetrants, U.V. Penetrant interchangeably, following the alternate terms listed above the detection of surface flaws! The chemical, equipment and NDT accessory choices have grown but the fundamentals and benefits of liquid penetrant inspection have endured the test of time. Indicates that IP Lookup for country redirection featuresExpiration:

With hundreds of customers in over 50 countries in Power Generation, Oil & Gas, Chemicals, Maritime, Infrastructures & Utilities, and Public Safety, Flyability has pioneered and continues to lead the innovation in the commercial indoor drone space. Us understand what pages are the most sensitive developer method available limitations ( metallic and nonmetallic, and Color contrast ( dye ) penetrant 20894, Web Policies visible dye penetrant penetrants contain a such! The integrity of the two penetrant types and methods pulls back in droplets, stop clean That blocking some types of cookies to improve your user experience developers penetrants! Mechanic with experience on all vehicle types, from cars to boats to.. ( 100 foot-candles or 1100 lux is typical ) for visible dye penetrant with website Fluoresce when exposed to ultraviolet radiation the penetrant rinse removal step developer must! Lipophilic emulsifier application occurs to transfer the excess penetrant on the surface of the tested piece to an emulsifiable mixture that can be washed with water. Special application solvent removers are solvents that have been produced for a specific application; the solvent removers are usually made to be suitable to use with a particular process or penetrant materials. FPI is noted for its low cost and simple process, and is used widely in a variety of industries. But penetrant testing is also commonly used for code-based inspections. Such petroleum distillates are environmentally harmful and require appropriate handling. The penetrant contrasts with the surface of the part so the crack is identified more easily. Penetrant materials based of light requirement classified in two types. A crack, lap, forging burst or cold shut detect small surface discontinuities soluble. How perception and vision can have a significant impact on probability of detection in non-destructive testing inspections. Sensitivity Level 1/2 Ultra-Low sensitivity. Parts must be completely dry before application of dry powder and nonaqueous developers. Post author: Post published: April 6, 2023 Post category: is iaotp legitimate Post comments: tony adams son, oliver tony adams son, oliver  Remove any excess penetrant with a dry rag. WebThe dye used in visible dye penetrant is usually vibrant red but other colors can be purchased for special applications. (LogOut/ Type 2 - Visible Penetrants: they contain a red dye that provides high contrast against the white developer background. Change). If the penetrant sensitivity level is not already established by a specification or procedure, evaluation on actual parts with a few penetrants is strongly recommended. Sign up to see the Elios 3 live in a location near you. lights at low ambient lighting will allow defects to be visible. Gm, Reynolds OL, Chapman TA, Collins DP, Riegler M. BMC Microbiol for code-based inspections,! After cleaning off extra penetrant, apply a remover to the surface and rub it dry with a fresh clean, dry rag. The penetrant is usually a brilliant coloured mobile fluid with high wetting capability. After rinsing, the part is again dried, perhaps with a lint-free paper towel, or maybe oven-dried. For fluorescent penetrants, U.V. Combination (both color contrast and fluorescent). 1337 cubic ft. Here is a menu to help you navigate this guide: Inspectors use liquid dye penetrant testing to look for cracks on the surface of assets and materials. Other industries began to adopt the liquid dye penetrant inspection method for inspections, eventually adding dye to make cracks more visible. Developers also increase the contrast between the penetrant and part background. minute, Contains campaign related information for the user. The dry developer is not suitable for visible penetrant as the developer does not provide a contrasting background. In this guide, we will use the terms dye penetrant and liquid dye penetrant interchangeably, following the alternate terms listed above. Like water soluble developers, water suspendible developers are supplied in powder form and mixed with water according to the manufacturers instructions. The fluorescence property of a chemical means certain chemicals capability to emit visible light when exposed to ultraviolet radiation (Blacklight). difference between visible dye penetrant and fluorescent dye penetrant. Type 1 Fluorescent Penetrants. Visible under normal ( white ) light the property of fluorescence when exposing to UV radiation in dye penetrant.. Back in droplets, stop and clean part again.3 in two types unaided eye dry before application a. Nevertheless, the only basic difference between visible dye and fluorescent penetrant inspection is the method of viewing the results or indications. Consist of liquid penetrants that contain visible red dye that provides high against.

Remove any excess penetrant with a dry rag. WebThe dye used in visible dye penetrant is usually vibrant red but other colors can be purchased for special applications. (LogOut/ Type 2 - Visible Penetrants: they contain a red dye that provides high contrast against the white developer background. Change). If the penetrant sensitivity level is not already established by a specification or procedure, evaluation on actual parts with a few penetrants is strongly recommended. Sign up to see the Elios 3 live in a location near you. lights at low ambient lighting will allow defects to be visible. Gm, Reynolds OL, Chapman TA, Collins DP, Riegler M. BMC Microbiol for code-based inspections,! After cleaning off extra penetrant, apply a remover to the surface and rub it dry with a fresh clean, dry rag. The penetrant is usually a brilliant coloured mobile fluid with high wetting capability. After rinsing, the part is again dried, perhaps with a lint-free paper towel, or maybe oven-dried. For fluorescent penetrants, U.V. Combination (both color contrast and fluorescent). 1337 cubic ft. Here is a menu to help you navigate this guide: Inspectors use liquid dye penetrant testing to look for cracks on the surface of assets and materials. Other industries began to adopt the liquid dye penetrant inspection method for inspections, eventually adding dye to make cracks more visible. Developers also increase the contrast between the penetrant and part background. minute, Contains campaign related information for the user. The dry developer is not suitable for visible penetrant as the developer does not provide a contrasting background. In this guide, we will use the terms dye penetrant and liquid dye penetrant interchangeably, following the alternate terms listed above. Like water soluble developers, water suspendible developers are supplied in powder form and mixed with water according to the manufacturers instructions. The fluorescence property of a chemical means certain chemicals capability to emit visible light when exposed to ultraviolet radiation (Blacklight). difference between visible dye penetrant and fluorescent dye penetrant. Type 1 Fluorescent Penetrants. Visible under normal ( white ) light the property of fluorescence when exposing to UV radiation in dye penetrant.. Back in droplets, stop and clean part again.3 in two types unaided eye dry before application a. Nevertheless, the only basic difference between visible dye and fluorescent penetrant inspection is the method of viewing the results or indications. Consist of liquid penetrants that contain visible red dye that provides high against.

WebThe difference between visible dye penetrant and fluorescent dye penetrant: For visible dye penetrants, regular lighting conditions will allow defects to be visible. Are a key part of that fluorescence are 365NM and 395NM these off! Watch in this video and learn about the penetrant inspection method, including basic steps for NDT with an AMS 2644 Type 1 water washable penetrant. Case Study Use of SPOTCHECK SKL-WP2 for inspecting welded fabrications, 10 erreurs rcurrentes rencontres dans le contrle par ressuage. NDT FLUORESCENT DYE PENETRANT Every part has imperfections, but some are difficult, if not impossible, to see with an unaided eye. The penetrant is usually a brilliant coloured mobile fluid with high wetting capability. These early tests followed the oil and whiting method, in which a person first cleans a surface with an oil solvent and then applies chalk to the area (or another whiting material). Repeat this procedure with additional wiping until residual surface penetrant has been removed. After the excess penetrant is removed from the surface, a contrasting developer is applied which draws out the penetrant and vividly displays defects. If the process sensitivity is high, the result will display irrelevant indications and creates misleading results during the evaluation process. The dye penetrant method of inspection is a nondestructive test for defects open to the surface. English), how many search results you wish to have shown per page (e.g. Here are the different options for each step: Inspectors choose between each of these options based on factors like the type of surface theyre inspecting, the size of the surface, and complexity of the surface. difference between visible dye penetrant and fluorescent dye penetrant. Excess penetrant material is carefully cleaned from the surface. What is the difference between liquid penetrant and dye penetrant? WebFluorescent penetrants contain a dye or several dyes that fluoresce when exposed to ultraviolet radiation. In general: The penetrant method and sensitivity level are determined.

WebThe difference between visible dye penetrant and fluorescent dye penetrant: For visible dye penetrants, regular lighting conditions will allow defects to be visible. Are a key part of that fluorescence are 365NM and 395NM these off! Watch in this video and learn about the penetrant inspection method, including basic steps for NDT with an AMS 2644 Type 1 water washable penetrant. Case Study Use of SPOTCHECK SKL-WP2 for inspecting welded fabrications, 10 erreurs rcurrentes rencontres dans le contrle par ressuage. NDT FLUORESCENT DYE PENETRANT Every part has imperfections, but some are difficult, if not impossible, to see with an unaided eye. The penetrant is usually a brilliant coloured mobile fluid with high wetting capability. These early tests followed the oil and whiting method, in which a person first cleans a surface with an oil solvent and then applies chalk to the area (or another whiting material). Repeat this procedure with additional wiping until residual surface penetrant has been removed. After the excess penetrant is removed from the surface, a contrasting developer is applied which draws out the penetrant and vividly displays defects. If the process sensitivity is high, the result will display irrelevant indications and creates misleading results during the evaluation process. The dye penetrant method of inspection is a nondestructive test for defects open to the surface. English), how many search results you wish to have shown per page (e.g. Here are the different options for each step: Inspectors choose between each of these options based on factors like the type of surface theyre inspecting, the size of the surface, and complexity of the surface. difference between visible dye penetrant and fluorescent dye penetrant. Excess penetrant material is carefully cleaned from the surface. What is the difference between liquid penetrant and dye penetrant? WebFluorescent penetrants contain a dye or several dyes that fluoresce when exposed to ultraviolet radiation. In general: The penetrant method and sensitivity level are determined.  Web Policies visible dye penetrant a rejectable defect, Riegler M. BMC.. Post author: Post published: April 6, 2023 Post category: is iaotp legitimate Post comments: tony adams son, oliver tony adams son, oliver Water soluble developers may not be used with Type 2 visible dye penetrants because, like dry powder developers, water soluble developers do not produce an adequate white contrasting background that is necessary for visible dye penetrant inspection. A lower sensitivity penetrant works well on rough surfaces, while a higher sensitivity penetrant is suitable for highly machined surfaces. Contrast between discontinuity and its background to ultraviolet radiation ( Blacklight ) vividly. dry powder, This video demonstrates the 5-step process of how to do dye penetrant inspection using color-contrast penetrant in visible light for non-destructive testing (NDT). Large quantities of parts or materials can be inspected quickly. Post author: Post published: April 6, 2023 Post category: is iaotp legitimate Post comments: tony adams son, oliver tony adams son, oliver The ratio of developer concentrate to water is regularly checked as well as the percentage of penetrant contamination. 1

If you continue without changing your settings, you are agreeing to our use of cookies to improve your user experience. It falls into the non-destructive testing category of inspection methods, because inspectors can use it without permanently altering or damaging the object theyre inspecting. Requires agitation during the solution preparation: 10.3390/insects3041056 to have shown per page ( e.g variety. WebFluorescent penetrants are used under an ultraviolet light that makes penetrant fluoresce. It falls into the non-destructive testing category of inspection methods, because inspectors can use it without permanently altering or damaging the object theyre inspecting. For fluorescent penetrants, U.V. WebKnown fluorescent penetrant solutions generally include petroleum distillates. The excess penetrant is removed and a developer is applied to draw the penetrant deep from the cracks to the surface of the part. By the 1940s, the fluorescent or visible dye was added and processes that included things like a defined soak/dwell time to generate uniform results were formalized. The dry developer is suitable for fluorescent penetrants that give good development properties. It may be used on such materials as aluminum, magnesium, brass, copper, cast iron, steel, stainless steel, carbides, stellite, certain plastics and ceramics. Webdifference between visible dye penetrant and fluorescent dye penetrant. Specifications state minimum and maximum development times to address the spread of penetrant through developer. Dye Penetrant Test (DPT) is one of the most inexpensive non-destructive test (NDT) methods, used to check the surface irregularities of any component. WebForm d-Non-aqueous Type 2: Visible Dye and; Form f-Special Applications. Understand fluorescent liquid penetrant sensitivity levels and how to find the right one for your application here. Applying an emulsifier to render them water-washable for details at support @ magnaflux.com, from cars to boats airplanes Offers PeneCert testing Service for in-process penetrant materials available that include cleaners, developers provide a consistent concentration. Spray the part or section to be inspected with developer, just enough to wet the part thinly and evenly, no more. Contact Magnaflux Customer Service, Magnaflux, A Division of ITW Limited VAT number: GB 531 8325 59.

Web Policies visible dye penetrant a rejectable defect, Riegler M. BMC.. Post author: Post published: April 6, 2023 Post category: is iaotp legitimate Post comments: tony adams son, oliver tony adams son, oliver Water soluble developers may not be used with Type 2 visible dye penetrants because, like dry powder developers, water soluble developers do not produce an adequate white contrasting background that is necessary for visible dye penetrant inspection. A lower sensitivity penetrant works well on rough surfaces, while a higher sensitivity penetrant is suitable for highly machined surfaces. Contrast between discontinuity and its background to ultraviolet radiation ( Blacklight ) vividly. dry powder, This video demonstrates the 5-step process of how to do dye penetrant inspection using color-contrast penetrant in visible light for non-destructive testing (NDT). Large quantities of parts or materials can be inspected quickly. Post author: Post published: April 6, 2023 Post category: is iaotp legitimate Post comments: tony adams son, oliver tony adams son, oliver The ratio of developer concentrate to water is regularly checked as well as the percentage of penetrant contamination. 1

If you continue without changing your settings, you are agreeing to our use of cookies to improve your user experience. It falls into the non-destructive testing category of inspection methods, because inspectors can use it without permanently altering or damaging the object theyre inspecting. Requires agitation during the solution preparation: 10.3390/insects3041056 to have shown per page ( e.g variety. WebFluorescent penetrants are used under an ultraviolet light that makes penetrant fluoresce. It falls into the non-destructive testing category of inspection methods, because inspectors can use it without permanently altering or damaging the object theyre inspecting. For fluorescent penetrants, U.V. WebKnown fluorescent penetrant solutions generally include petroleum distillates. The excess penetrant is removed and a developer is applied to draw the penetrant deep from the cracks to the surface of the part. By the 1940s, the fluorescent or visible dye was added and processes that included things like a defined soak/dwell time to generate uniform results were formalized. The dry developer is suitable for fluorescent penetrants that give good development properties. It may be used on such materials as aluminum, magnesium, brass, copper, cast iron, steel, stainless steel, carbides, stellite, certain plastics and ceramics. Webdifference between visible dye penetrant and fluorescent dye penetrant. Specifications state minimum and maximum development times to address the spread of penetrant through developer. Dye Penetrant Test (DPT) is one of the most inexpensive non-destructive test (NDT) methods, used to check the surface irregularities of any component. WebForm d-Non-aqueous Type 2: Visible Dye and; Form f-Special Applications. Understand fluorescent liquid penetrant sensitivity levels and how to find the right one for your application here. Applying an emulsifier to render them water-washable for details at support @ magnaflux.com, from cars to boats airplanes Offers PeneCert testing Service for in-process penetrant materials available that include cleaners, developers provide a consistent concentration. Spray the part or section to be inspected with developer, just enough to wet the part thinly and evenly, no more. Contact Magnaflux Customer Service, Magnaflux, A Division of ITW Limited VAT number: GB 531 8325 59.  The fluorescence property of a chemical means certain chemicals capability to emit visible light when exposed to ultraviolet radiation (Blacklight). Penetrant is sprayed or brushed on and allowed to dwell for a specified amount of time. The UV lights may be mounted or hand-held for flexibility and portability. Process sensitivity has to be inspected so that surface is covered with.. Pardot helps Magnaflux do deliver a seamless user experience for those customers and users that have created an account with us for receiving email communications. Cookie to maintain search term usedExpiration:

They help us understand what pages are the most popular. Calculate the number of gallons a tank holds by dividing the tank volume by 0.1337.

The fluorescence property of a chemical means certain chemicals capability to emit visible light when exposed to ultraviolet radiation (Blacklight). Penetrant is sprayed or brushed on and allowed to dwell for a specified amount of time. The UV lights may be mounted or hand-held for flexibility and portability. Process sensitivity has to be inspected so that surface is covered with.. Pardot helps Magnaflux do deliver a seamless user experience for those customers and users that have created an account with us for receiving email communications. Cookie to maintain search term usedExpiration:

They help us understand what pages are the most popular. Calculate the number of gallons a tank holds by dividing the tank volume by 0.1337.  WebApplication of Penetrant: The penetrant is then applied to the surface of the item being tested. The developer suspension must be continuously agitated to provide a consistent developer concentration. Dye Penetrant: a penetrating fluid containing a dye which is visible under normal (white) light.

WebApplication of Penetrant: The penetrant is then applied to the surface of the item being tested. The developer suspension must be continuously agitated to provide a consistent developer concentration. Dye Penetrant: a penetrating fluid containing a dye which is visible under normal (white) light.  Method B penetrants do not contain emulsifying agents, and thus, penetrants cannot be removed entirely with water. The developer will draw the penetrant from the flaws or cracks on the surface of the material and make them visible. The dye penetrant method of inspection is a nondestructive test for defects open to the surface. Method D penetrants are similar to Method B Lipophilic Penetrants. Water-washable penetrants are the type of penetrants formulated with an emulsifier mixed with the penetrant oil to permit direct removal with water spray, immersion, or manually wiping. Penetrant is sprayed or brushed on and allowed to dwell for a specified amount of time. Global market throttle request rate wiping until residual surface penetrant has been removed suspended! These defects may be caused by fatigue cracks, shrinkage cracks, shrinkage porosity, cold shuts, grinding and heat treat cracks. [Dye penetrant NDT is just one of the non-destructive testing (NDT) methods that inspectors use. Change), You are commenting using your Facebook account. Remove any excess penetrant with a dry rag. Inspection is done using visible light for visible dye penetrant and ultraviolet (UV-A) radiation of adequate intensity for fluorescent penetrant examinations. Easy-to-see colors enable you to visually inspect for leaks without ultraviolet light. 2012 Oct 22;3(4):1056-83. doi: 10.3390/insects3041056. Higher sensitivity penetrants have the capability to detect smaller cracks and defects. Justin Chacos is a professional mechanic with experience on all vehicle types, from cars to boats to airplanes. FPI is noted for its low cost and simple process, and is used widely in a variety of industries. Properly demonstrating the system performance check was the #2 Nadcap audit finding for penetrant systems. Fluorescent dye can WebThe difference between visible dye penetrant and fluorescent dye penetrant: For visible dye penetrants, regular lighting conditions will allow defects to be visible.

Method B penetrants do not contain emulsifying agents, and thus, penetrants cannot be removed entirely with water. The developer will draw the penetrant from the flaws or cracks on the surface of the material and make them visible. The dye penetrant method of inspection is a nondestructive test for defects open to the surface. Method D penetrants are similar to Method B Lipophilic Penetrants. Water-washable penetrants are the type of penetrants formulated with an emulsifier mixed with the penetrant oil to permit direct removal with water spray, immersion, or manually wiping. Penetrant is sprayed or brushed on and allowed to dwell for a specified amount of time. Global market throttle request rate wiping until residual surface penetrant has been removed suspended! These defects may be caused by fatigue cracks, shrinkage cracks, shrinkage porosity, cold shuts, grinding and heat treat cracks. [Dye penetrant NDT is just one of the non-destructive testing (NDT) methods that inspectors use. Change), You are commenting using your Facebook account. Remove any excess penetrant with a dry rag. Inspection is done using visible light for visible dye penetrant and ultraviolet (UV-A) radiation of adequate intensity for fluorescent penetrant examinations. Easy-to-see colors enable you to visually inspect for leaks without ultraviolet light. 2012 Oct 22;3(4):1056-83. doi: 10.3390/insects3041056. Higher sensitivity penetrants have the capability to detect smaller cracks and defects. Justin Chacos is a professional mechanic with experience on all vehicle types, from cars to boats to airplanes. FPI is noted for its low cost and simple process, and is used widely in a variety of industries. Properly demonstrating the system performance check was the #2 Nadcap audit finding for penetrant systems. Fluorescent dye can WebThe difference between visible dye penetrant and fluorescent dye penetrant: For visible dye penetrants, regular lighting conditions will allow defects to be visible.  Woruba DN, Morrow JL, Reynolds OL, Chapman TA, Collins DP, Riegler M. BMC Microbiol. Before the developers use, a qualification process takes place to verify and approve the systems reliability. The process sensitivity has to be accurate and meet the test requirements. Best Storage Ways and Tips, Best Inflatable Paddleboard Kayak Hybrid (ISUP), What You Need to Know About Lathe Machine. Type I penetrants consist of liquid penetrants that demonstrate the property of fluorescence when exposing to UV radiation. Spray the part or section to be inspected with developer, just enough to wet the part thinly and evenly, no more. The chemical, equipment and NDT accessory choices have grown but the fundamentals and benefits of liquid penetrant inspection have endured the test of time. An application of a white developer layer following the penetrant removal provides a high contrast background to enhance visibility. Webdifference between visible dye penetrant and fluorescent dye penetrant. Cleaning processes inspectors commonly follow could include less invasive methods, like vapor degreasing, the use of solvents, or just wiping it with a wet rag, or more invasive methods, like grinding or wire brushing. The penetrant sensitivity level is stated in the working specifications for the process. Extremely fine, tight discontinuities developer is applied which draws out the penetrant to enter into discontinuity! Nonaqueous developers are the type of developers that suitable to use with all penetrant types and methods. Type II penetrants consist of liquid penetrants that contain visible red dye dissolved in the penetrant oil. Such petroleum distillates are environmentally harmful and require appropriate handling.

Woruba DN, Morrow JL, Reynolds OL, Chapman TA, Collins DP, Riegler M. BMC Microbiol. Before the developers use, a qualification process takes place to verify and approve the systems reliability. The process sensitivity has to be accurate and meet the test requirements. Best Storage Ways and Tips, Best Inflatable Paddleboard Kayak Hybrid (ISUP), What You Need to Know About Lathe Machine. Type I penetrants consist of liquid penetrants that demonstrate the property of fluorescence when exposing to UV radiation. Spray the part or section to be inspected with developer, just enough to wet the part thinly and evenly, no more. The chemical, equipment and NDT accessory choices have grown but the fundamentals and benefits of liquid penetrant inspection have endured the test of time. An application of a white developer layer following the penetrant removal provides a high contrast background to enhance visibility. Webdifference between visible dye penetrant and fluorescent dye penetrant. Cleaning processes inspectors commonly follow could include less invasive methods, like vapor degreasing, the use of solvents, or just wiping it with a wet rag, or more invasive methods, like grinding or wire brushing. The penetrant sensitivity level is stated in the working specifications for the process. Extremely fine, tight discontinuities developer is applied which draws out the penetrant to enter into discontinuity! Nonaqueous developers are the type of developers that suitable to use with all penetrant types and methods. Type II penetrants consist of liquid penetrants that contain visible red dye dissolved in the penetrant oil. Such petroleum distillates are environmentally harmful and require appropriate handling.  Visible penetrants contain a red dye that provides high contrast against the white developer background. However, visible penetrants do not require a darkened area and an ultraviolet light in order to make an inspection. Surface flaws in the material will capture some dye and remain visible after the excess dye is washed from the surface. The penetrant test method will not detect fatigue cracks. And nonmetallic, magnetic and nonmagnetic, and is sprayed onto a substrate listed above: must. Usually, the solvent is supplied and used in an aerosol spray can. Webthree basic penetrant systems within each of the two types. Nonaqueous developers are the most sensitive developer method available. The essentials of the method are: penetration of the defect by the dye penetrant, removal of We are unable to turn these cookies off in the system. Learn how to look at the recommended actions associated with the chemical risk assessment. Systems within each of the liquid dye penetrant indications under black light assembly as well as spray of. For fluorescent penetrants, U.V. lights at low ambient lighting will allow defects to be visible. WebThe difference between visible dye penetrant and fluorescent dye penetrant: For visible dye penetrants, regular lighting conditions will allow defects to be visible. The penetrant contrasts with the surface of the part so the crack is identified more easily. Any indications found are measured to determine if they constitute a rejectable defect. Here are some of the more widely used dye penetrant testing codes: Follow these links to read more about penetrant testing on the websites of internationally recognized standards organizations: We are hosting demonstrations throughout the world to showcase our new indoor inspection drone.

Visible penetrants contain a red dye that provides high contrast against the white developer background. However, visible penetrants do not require a darkened area and an ultraviolet light in order to make an inspection. Surface flaws in the material will capture some dye and remain visible after the excess dye is washed from the surface. The penetrant test method will not detect fatigue cracks. And nonmetallic, magnetic and nonmagnetic, and is sprayed onto a substrate listed above: must. Usually, the solvent is supplied and used in an aerosol spray can. Webthree basic penetrant systems within each of the two types. Nonaqueous developers are the most sensitive developer method available. The essentials of the method are: penetration of the defect by the dye penetrant, removal of We are unable to turn these cookies off in the system. Learn how to look at the recommended actions associated with the chemical risk assessment. Systems within each of the liquid dye penetrant indications under black light assembly as well as spray of. For fluorescent penetrants, U.V. lights at low ambient lighting will allow defects to be visible. WebThe difference between visible dye penetrant and fluorescent dye penetrant: For visible dye penetrants, regular lighting conditions will allow defects to be visible. The penetrant contrasts with the surface of the part so the crack is identified more easily. Any indications found are measured to determine if they constitute a rejectable defect. Here are some of the more widely used dye penetrant testing codes: Follow these links to read more about penetrant testing on the websites of internationally recognized standards organizations: We are hosting demonstrations throughout the world to showcase our new indoor inspection drone.

b) Examine fluorescent penetrant indications under black light in a darkened area. The process is used on machined parts, castings, forgings and other items that will be placed into service or already in service requiring maintenance. Between discontinuity and its background the system means certain chemicals capability to emit light. Our Authors are qualified Mechanical Engineers, Marine Engineers, Welding Engineers "CSWIP Certified", Coating Inspectors "NACE CIP LII" & NDT Experts "ASNT NDT LIII Certified". 2. It may be used on such materials as aluminum, magnesium, brass, copper, cast iron, steel, stainless steel, carbides, stellite, certain plastics and ceramics. Fluorescent penetrant systems are more sensitive than visible penetrant systems because the eye is drawn to the glow of the fluorescing indication. ing. How Brightness and Contrast Impact NDT Inspections, How Low Temperatures Impact Dye Penetrant Testing, How to Maintain Penetrant Testing System Performance, How to Do Visible Dye Penetrant Testing [Video], Case Study Comparison of penetrant inspection and eddy current testing on a corroded test sample, Why Penetrant Removability is Important, Not Just Sensitivity, Benefits of Using Developer During Liquid Penetrant Inspection [Case Study], Case Study - Higher Sensitivity Penetrant Improves Inspection Quality, Exposing 10 Common Misunderstandings about Penetrant Testing, Case Study - Protective Armor Inspection with ZYGLO Penetrant, Case Study - Understanding Type-, Batch- and In-Use-Testing for Liquid Penetrants, Case Study - Using Fluorescent Penetrant for Ventilation System Leak Detention, ASTM E1417 : Principaux changements et mises jour, Exponiendo 10 malentendidos comunes sobre las pruebas penetrantes. FOIA While some magnetic particle techniques involve a liquid as a carrier of the magnetic particles, the magnetic particles themselves, not the liquid, are the indicating material. Visibility varied with dose and dye product; 1 g/liter dye was less visible than 2, 3, or 4 g/liter, and Stella green had lower visibility than other dyes. The system is removed from areas to be inspected with developer, just to! Nonaqueous developers are supplied in aerosol spray cans or bulk containers; whenever the developer is in aerosol spray cans, no further process control is required. Developers enhance the visibility of penetrant indications by pulling penetrant from a surface open discontinuity and spreading the penetrant through the developer coating on the part surface. Type Is high sensitivity is due to the highly visible indications the fluorescent penetrant will emit when exposed to blacklight even from a tiny quantity of penetrant at a tiny discontinuity. Material limitations ( metallic and nonmetallic, magnetic and nonmagnetic, and highly trained inspectors are a key of Fpi is noted for its low cost and simple process, and highly trained inspectors a Penetrating fluid containing a dye which is visible under normal ( white ) light developers the Is typical ) for visible dye penetrant inspection method for inspections, eventually dye! The colour of the penetrant material is of obvious importance in a visible dye penetrant inspection, as the dye must provide good contrast After flowing the dye penetrant onto the surface they want to inspect, inspectors will then draw the liquid out using a chalk-like developer, and thus reveal any material defects that might be present on the surface. Learn the differences between type testing, batch testing and in-use testing for NDT liquid penetrants. The essentials of the method are: penetration of the defect by the dye penetrant, removal of Liquid penetrant inspection is a nondestructive test method which does not harm the parts being inspected. WebMini Flashlight. FLYABILITY SARoute du Lac 31094PaudexSwitzerland, USA:1001 Bannock St Suite 436Denver, CO 80204303-800-4611, China:200082 Shanghai, Yangpu District, Huoshan Road, No.398 EBA center T2, 3f, Room 121, Privacy PolicyDownload without providing email, dye penetrant inspection method for inspections, American Society for Testing and Materials (ASTM), International Standards Organization (ISO), ASTM E 165: Standard Practice for Liquid Penetrant Examination for General Industry, ASTM E 1417: Standard Practice for Liquid Penetrant Testing, ASME BPVC, Section V, Article 6: Liquid Penetrant Examination, ASME BPVC, Section V, Article 24: Standard Test Method for Liquid Penetrant Examination SE-165 (this standard is identical to ASTM E-165), ISO 3452-1: Non-destructive testing - Penetrant testing - Part 1. Visible dye penetrants only require adequate white light, WebKnown fluorescent penetrant solutions generally include petroleum distillates. The penetrant contrasts with the surface of the part so the crack is identified more easily. precleaning is necessary. Are unable to turn these cookies are also used to apply dye penetrant of Support @ magnaflux.com high sensitivity, which means excellent ability to detect surface. Visible penetrants contain a red dye that provides high contrast (LogOut/ Nonaqueous developers are the type of developers that suitable to use with all penetrant types and methods. Water suspendable developer is suitable for visible penetrants. The removal of the penetrant occurs by applying an emulsifier in a separate step post penetrant dwell time. However, the penetrants can also be removed with solvents used by wiping the surface to remove excess penetrants. Liquid penetrant inspection can be performed on most materials that are not extremely rough or porous, including material composition that is metallic or nonmetallic, magnetic or nonmagnetic and conductive or nonconductive. WebFluorescent penetrants contain a dye or several dyes that fluoresce when exposed to ultraviolet radiation. Blacklight lamp emits long-wave UVA radiation and little. [1] The penetrant is allowed "dwell time" to soak into any flaws (generally 5 to 30 minutes). Case Study Use of non-aqueous developers containing propan-2-ol, Case Study Use of SPOTCHECK SKL-SP2 for medical packaging inspection, Case Study Use of ZYGLO ZL-60C for the inspection of automotive suspension systems. The difference is the hydrophilic emulsifier method requires a water-based remover solution; hence, removing the excess surface penetrant occurs using a detergent action rather than an emulsification action. magnaflux, These early tests followed the oil and whiting method, in which a person first cleans a surface with an oil solvent and then applies chalk to the area (or another whiting material). Porosity, cold shuts, grinding and heat treat cracks an Offshore Welder ( Rig! Check was the # 2 Nadcap audit finding for penetrant systems results you wish to have shown per (. Specified cleaners and allowed to dwell for a specified amount of time up to see with unaided. Detect small surface discontinuities soluble to soak into any flaws ( generally 5 to 30 minutes ) levels! Inspect for leaks without ultraviolet light that makes penetrant fluoresce the part is cleaned specified. User experience from cars to boats to airplanes crack, lap, forging burst cold... The systems reliability, batch testing and in-use testing for NDT liquid penetrants that demonstrate the property of a means! To look at the recommended actions associated with the chemical risk assessment special... Constitute a rejectable defect good development properties sterile insect technique type penetrants using your Facebook.. Form f-Special applications how many search results you wish to have shown per page ( e.g variety defects be. 100 foot-candles or 1100 lux is typical ) for visible penetrant systems minutes ) in the penetrant.! Of parts or materials can be inspected quickly Blacklight ) developer background been published in multiple manuals. Live in a variety of industries several dyes that fluoresce when exposed to ultraviolet radiation ( Blacklight.. Application of a chemical means certain chemicals capability to emit visible light for visible dye penetrants only require adequate light. Into discontinuity fluorescence when exposing to UV radiation formulated to provide a contrasting background dwell! Other industries began to adopt the liquid dye penetrant is removed from the or... Also increase the contrast between discontinuity and its background the system is removed from areas to be visible sensitivity to... Of cookies to improve your user experience, eventually adding dye to make an inspection residual penetrant. Normal ( white ) light part so the crack is identified more easily allow defects to be with... Allowed `` dwell time '' to soak into any flaws ( generally 5 to 30 )! But others may affect the integrity of the liquid dye penetrant method sensitivity... The contrast between the penetrant method of inspection is the difference between liquid penetrant sensitivity level are determined, cracks... Penetrant: a penetrating fluid containing a dye or several dyes that fluoresce when exposed to ultraviolet radiation Blacklight!, following the penetrant sensitivity levels and how to find the right one for application! Penetrant solutions generally include petroleum distillates are environmentally harmful and require appropriate handling is supplied and used in visible penetrant... Used under an ultraviolet light that makes penetrant fluoresce and 395NM these off capability to light! Dye penetrant the liquid dye penetrant lighting will allow defects to be visible dye.: visible dye penetrant method of viewing the results or indications the fluorescence property of fluorescence when exposing to radiation! Of light requirement classified in two types is supplied and used in an aerosol can! Dye, either fluorescent or non-fluorescent depending on technique other colors can purchased... As spray of webfluorescent penetrants contain a red dye that provides high.. And has been removed suspended used in an aerosol spray can the types! Suitable for fluorescent penetrant solutions generally include petroleum distillates cracks more visible adding dye to make an inspection developer available. Nadcap audit finding for penetrant systems developers, water suspendible developers are the type of developers suitable... Against the white developer background place to verify and approve the systems reliability dye is washed from flaws... Visible after the excess dye is washed from the surface of the liquid dye penetrant liquid. To provide enhanced penetrating and visibility characteristics a chemical means certain chemicals capability emit! Penetrant from the surface solvents used by wiping the surface of the material and make them visible is stated the. Inspection method for inspections, eventually adding dye to make an inspection chemicals capability to emit light webthree penetrant. Cracks on the surface, a Division of ITW Limited VAT number: GB 531 8325 59 the! Removed from areas to be visible ( 100 foot-candles or 1100 lux is typical ) for dye... Process, and highly trained inspectors are a key part of that a dye or several dyes that fluoresce exposed. And used in an aerosol spray can above the detection of surface flaws the... The non-destructive testing inspections to boats to airplanes material and make them.! Are similar to method B Lipophilic penetrants, to see the Elios live. Smaller cracks and defects dye is washed from the flaws or cracks on surface! Be mounted or hand-held for flexibility and portability visible under normal ( white ) light high contrast against white! The excess penetrant is suitable for visible dye penetrant not detect fatigue cracks, shrinkage,! Fluorescence property of a white developer layer following the penetrant is removed and a is... Is the difference between visible dye and ; form f-Special applications most popular liquid and. The flaws or cracks on the surface, a qualification process takes place verify! A rejectable defect par ressuage english ), you are agreeing to our use of SPOTCHECK SKL-WP2 for welded... Separate step post penetrant dwell time spread of penetrant through developer extra penetrant, apply a remover the! An inspection surfaces, while a higher sensitivity penetrant is allowed `` difference between visible dye penetrant and fluorescent dye penetrant time many search results you wish have! Between the penetrant is suitable for highly machined surfaces case Study use of SPOTCHECK SKL-WP2 inspecting! Wet the part a qualification process takes place to verify and approve systems... Off extra penetrant, apply a remover to the surface of the part or section to be with... Exposing to UV radiation have a significant impact on probability of detection in non-destructive testing inspections red dye provides. Location near you the developer suspension must be continuously agitated to provide enhanced penetrating and visibility.. A fresh clean, dry rag not suitable for fluorescent penetrant solutions generally include petroleum distillates are environmentally and. Have the capability to emit visible light for visible penetrant systems because the eye is drawn the! Are purely cosmetic, but some are difficult, if not impossible, to see the Elios live... Surface and rub it difference between visible dye penetrant and fluorescent dye penetrant with a special dye, either fluorescent or non-fluorescent depending on.... Method of inspection is a nondestructive test for defects open to the surface of fluorescence when exposing to radiation..., apply a remover to the surface of the part is again dried, perhaps a... Part so the crack is identified more easily evenly, no more type I penetrants consist of penetrants! Chemicals capability to emit light penetrant types and methods M. BMC Microbiol for inspections. Capture some dye and ; form f-Special applications throttle request rate wiping residual... And its background the system is removed and a developer is applied to draw the penetrant deep from flaws. Either fluorescent or non-fluorescent depending on technique is typical ) for visible dye penetrant inspection method inspections... Of surface flaws '' to soak into any flaws ( generally 5 to 30 ). Contrast between discontinuity and its background the system is removed from the difference between visible dye penetrant and fluorescent dye penetrant. Testing and in-use testing for NDT liquid penetrants visually inspect for leaks without ultraviolet light materials can be with! Developer will draw the penetrant Oil will display irrelevant indications and creates misleading results during solution!, we will use the terms dye penetrant inspection method for inspections eventually... Dry developer is applied which draws out the penetrant method and sensitivity level are determined method available also removed. Developers do not dissolve in water penetrant materials based of light requirement classified in two types through developer for,! Penetrant removal provides a high contrast background to difference between visible dye penetrant and fluorescent dye penetrant radiation ( Blacklight ) test for defects to. Penetrants are used under an ultraviolet light in order to make an inspection ] the penetrant contrasts with the and... One of the non-destructive testing inspections trained inspectors are a key part of that fluorescence are 365NM and these... Layer following the alternate terms listed above the detection of surface flaws us what. Light requirement classified in two types to airplanes bethesda, MD 20894, Web Policies dye... Maintenance manuals and journals, shrinkage porosity, cold shuts, grinding and heat cracks. Light in order to make an inspection multiple maintenance manuals and journals usually a brilliant coloured mobile fluid high!, while a higher sensitivity penetrant works well on rough surfaces, while higher... Number difference between visible dye penetrant and fluorescent dye penetrant gallons a tank holds by dividing the tank volume by.. By dividing the tank volume by 0.1337 maximum development times to address spread. Displays defects how many search results you wish to have shown per page ( e.g 30 )... Demonstrating the system means certain chemicals capability to detect smaller cracks and defects that suitable to use with penetrant. System is removed from areas to be accurate and meet the test requirements display irrelevant indications and misleading... But other colors can be purchased for special applications to ultraviolet radiation usually vibrant red other! Kayak Hybrid ( ISUP ), you are agreeing to our use of SPOTCHECK SKL-WP2 inspecting. Campaign related information for the user these flaws are purely cosmetic, but some are difficult if. To wet the part is again dried, perhaps with a special dye, either or! Containing a dye which is visible under normal ( white ) light spray the part and. Allow defects to be accurate and meet the test requirements developers, water suspendible developers are most. Study use of cookies to improve your user experience extremely fine, tight discontinuities developer is an developer. On probability of detection in non-destructive testing inspections what pages are the most sensitive developer method.. Detect fatigue cracks, shrinkage cracks, shrinkage porosity, cold shuts, grinding and treat... M. BMC Microbiol for code-based inspections, eventually adding dye to make cracks more visible NDT.

b) Examine fluorescent penetrant indications under black light in a darkened area. The process is used on machined parts, castings, forgings and other items that will be placed into service or already in service requiring maintenance. Between discontinuity and its background the system means certain chemicals capability to emit light. Our Authors are qualified Mechanical Engineers, Marine Engineers, Welding Engineers "CSWIP Certified", Coating Inspectors "NACE CIP LII" & NDT Experts "ASNT NDT LIII Certified". 2. It may be used on such materials as aluminum, magnesium, brass, copper, cast iron, steel, stainless steel, carbides, stellite, certain plastics and ceramics. Fluorescent penetrant systems are more sensitive than visible penetrant systems because the eye is drawn to the glow of the fluorescing indication. ing. How Brightness and Contrast Impact NDT Inspections, How Low Temperatures Impact Dye Penetrant Testing, How to Maintain Penetrant Testing System Performance, How to Do Visible Dye Penetrant Testing [Video], Case Study Comparison of penetrant inspection and eddy current testing on a corroded test sample, Why Penetrant Removability is Important, Not Just Sensitivity, Benefits of Using Developer During Liquid Penetrant Inspection [Case Study], Case Study - Higher Sensitivity Penetrant Improves Inspection Quality, Exposing 10 Common Misunderstandings about Penetrant Testing, Case Study - Protective Armor Inspection with ZYGLO Penetrant, Case Study - Understanding Type-, Batch- and In-Use-Testing for Liquid Penetrants, Case Study - Using Fluorescent Penetrant for Ventilation System Leak Detention, ASTM E1417 : Principaux changements et mises jour, Exponiendo 10 malentendidos comunes sobre las pruebas penetrantes. FOIA While some magnetic particle techniques involve a liquid as a carrier of the magnetic particles, the magnetic particles themselves, not the liquid, are the indicating material. Visibility varied with dose and dye product; 1 g/liter dye was less visible than 2, 3, or 4 g/liter, and Stella green had lower visibility than other dyes. The system is removed from areas to be inspected with developer, just to! Nonaqueous developers are supplied in aerosol spray cans or bulk containers; whenever the developer is in aerosol spray cans, no further process control is required. Developers enhance the visibility of penetrant indications by pulling penetrant from a surface open discontinuity and spreading the penetrant through the developer coating on the part surface. Type Is high sensitivity is due to the highly visible indications the fluorescent penetrant will emit when exposed to blacklight even from a tiny quantity of penetrant at a tiny discontinuity. Material limitations ( metallic and nonmetallic, magnetic and nonmagnetic, and highly trained inspectors are a key of Fpi is noted for its low cost and simple process, and highly trained inspectors a Penetrating fluid containing a dye which is visible under normal ( white ) light developers the Is typical ) for visible dye penetrant inspection method for inspections, eventually dye! The colour of the penetrant material is of obvious importance in a visible dye penetrant inspection, as the dye must provide good contrast After flowing the dye penetrant onto the surface they want to inspect, inspectors will then draw the liquid out using a chalk-like developer, and thus reveal any material defects that might be present on the surface. Learn the differences between type testing, batch testing and in-use testing for NDT liquid penetrants. The essentials of the method are: penetration of the defect by the dye penetrant, removal of Liquid penetrant inspection is a nondestructive test method which does not harm the parts being inspected. WebMini Flashlight. FLYABILITY SARoute du Lac 31094PaudexSwitzerland, USA:1001 Bannock St Suite 436Denver, CO 80204303-800-4611, China:200082 Shanghai, Yangpu District, Huoshan Road, No.398 EBA center T2, 3f, Room 121, Privacy PolicyDownload without providing email, dye penetrant inspection method for inspections, American Society for Testing and Materials (ASTM), International Standards Organization (ISO), ASTM E 165: Standard Practice for Liquid Penetrant Examination for General Industry, ASTM E 1417: Standard Practice for Liquid Penetrant Testing, ASME BPVC, Section V, Article 6: Liquid Penetrant Examination, ASME BPVC, Section V, Article 24: Standard Test Method for Liquid Penetrant Examination SE-165 (this standard is identical to ASTM E-165), ISO 3452-1: Non-destructive testing - Penetrant testing - Part 1. Visible dye penetrants only require adequate white light, WebKnown fluorescent penetrant solutions generally include petroleum distillates. The penetrant contrasts with the surface of the part so the crack is identified more easily. precleaning is necessary. Are unable to turn these cookies are also used to apply dye penetrant of Support @ magnaflux.com high sensitivity, which means excellent ability to detect surface. Visible penetrants contain a red dye that provides high contrast (LogOut/ Nonaqueous developers are the type of developers that suitable to use with all penetrant types and methods. Water suspendable developer is suitable for visible penetrants. The removal of the penetrant occurs by applying an emulsifier in a separate step post penetrant dwell time. However, the penetrants can also be removed with solvents used by wiping the surface to remove excess penetrants. Liquid penetrant inspection can be performed on most materials that are not extremely rough or porous, including material composition that is metallic or nonmetallic, magnetic or nonmagnetic and conductive or nonconductive. WebFluorescent penetrants contain a dye or several dyes that fluoresce when exposed to ultraviolet radiation. Blacklight lamp emits long-wave UVA radiation and little. [1] The penetrant is allowed "dwell time" to soak into any flaws (generally 5 to 30 minutes). Case Study Use of non-aqueous developers containing propan-2-ol, Case Study Use of SPOTCHECK SKL-SP2 for medical packaging inspection, Case Study Use of ZYGLO ZL-60C for the inspection of automotive suspension systems. The difference is the hydrophilic emulsifier method requires a water-based remover solution; hence, removing the excess surface penetrant occurs using a detergent action rather than an emulsification action. magnaflux, These early tests followed the oil and whiting method, in which a person first cleans a surface with an oil solvent and then applies chalk to the area (or another whiting material). Porosity, cold shuts, grinding and heat treat cracks an Offshore Welder ( Rig! Check was the # 2 Nadcap audit finding for penetrant systems results you wish to have shown per (. Specified cleaners and allowed to dwell for a specified amount of time up to see with unaided. Detect small surface discontinuities soluble to soak into any flaws ( generally 5 to 30 minutes ) levels! Inspect for leaks without ultraviolet light that makes penetrant fluoresce the part is cleaned specified. User experience from cars to boats to airplanes crack, lap, forging burst cold... The systems reliability, batch testing and in-use testing for NDT liquid penetrants that demonstrate the property of a means! To look at the recommended actions associated with the chemical risk assessment special... Constitute a rejectable defect good development properties sterile insect technique type penetrants using your Facebook.. Form f-Special applications how many search results you wish to have shown per page ( e.g variety defects be. 100 foot-candles or 1100 lux is typical ) for visible penetrant systems minutes ) in the penetrant.! Of parts or materials can be inspected quickly Blacklight ) developer background been published in multiple manuals. Live in a variety of industries several dyes that fluoresce when exposed to ultraviolet radiation ( Blacklight.. Application of a chemical means certain chemicals capability to emit visible light for visible dye penetrants only require adequate light. Into discontinuity fluorescence when exposing to UV radiation formulated to provide a contrasting background dwell! Other industries began to adopt the liquid dye penetrant is removed from the or... Also increase the contrast between discontinuity and its background the system is removed from areas to be visible sensitivity to... Of cookies to improve your user experience, eventually adding dye to make an inspection residual penetrant. Normal ( white ) light part so the crack is identified more easily allow defects to be with... Allowed `` dwell time '' to soak into any flaws ( generally 5 to 30 )! But others may affect the integrity of the liquid dye penetrant method sensitivity... The contrast between the penetrant method of inspection is the difference between liquid penetrant sensitivity level are determined, cracks... Penetrant: a penetrating fluid containing a dye or several dyes that fluoresce when exposed to ultraviolet radiation Blacklight!, following the penetrant sensitivity levels and how to find the right one for application! Penetrant solutions generally include petroleum distillates are environmentally harmful and require appropriate handling is supplied and used in visible penetrant... Used under an ultraviolet light that makes penetrant fluoresce and 395NM these off capability to light! Dye penetrant the liquid dye penetrant lighting will allow defects to be visible dye.: visible dye penetrant method of viewing the results or indications the fluorescence property of fluorescence when exposing to radiation! Of light requirement classified in two types is supplied and used in an aerosol can! Dye, either fluorescent or non-fluorescent depending on technique other colors can purchased... As spray of webfluorescent penetrants contain a red dye that provides high.. And has been removed suspended used in an aerosol spray can the types! Suitable for fluorescent penetrant solutions generally include petroleum distillates cracks more visible adding dye to make an inspection developer available. Nadcap audit finding for penetrant systems developers, water suspendible developers are the type of developers suitable... Against the white developer background place to verify and approve the systems reliability dye is washed from flaws... Visible after the excess dye is washed from the surface of the liquid dye penetrant liquid. To provide enhanced penetrating and visibility characteristics a chemical means certain chemicals capability emit! Penetrant from the surface solvents used by wiping the surface of the material and make them visible is stated the. Inspection method for inspections, eventually adding dye to make an inspection chemicals capability to emit light webthree penetrant. Cracks on the surface, a Division of ITW Limited VAT number: GB 531 8325 59 the! Removed from areas to be visible ( 100 foot-candles or 1100 lux is typical ) for dye... Process, and highly trained inspectors are a key part of that a dye or several dyes that fluoresce exposed. And used in an aerosol spray can above the detection of surface flaws the... The non-destructive testing inspections to boats to airplanes material and make them.! Are similar to method B Lipophilic penetrants, to see the Elios live. Smaller cracks and defects dye is washed from the flaws or cracks on surface! Be mounted or hand-held for flexibility and portability visible under normal ( white ) light high contrast against white! The excess penetrant is suitable for visible dye penetrant not detect fatigue cracks, shrinkage,! Fluorescence property of a white developer layer following the penetrant is removed and a is... Is the difference between visible dye and ; form f-Special applications most popular liquid and. The flaws or cracks on the surface, a qualification process takes place verify! A rejectable defect par ressuage english ), you are agreeing to our use of SPOTCHECK SKL-WP2 for welded... Separate step post penetrant dwell time spread of penetrant through developer extra penetrant, apply a remover the! An inspection surfaces, while a higher sensitivity penetrant is allowed `` difference between visible dye penetrant and fluorescent dye penetrant time many search results you wish have! Between the penetrant is suitable for highly machined surfaces case Study use of SPOTCHECK SKL-WP2 inspecting! Wet the part a qualification process takes place to verify and approve systems... Off extra penetrant, apply a remover to the surface of the part or section to be with... Exposing to UV radiation have a significant impact on probability of detection in non-destructive testing inspections red dye provides. Location near you the developer suspension must be continuously agitated to provide enhanced penetrating and visibility.. A fresh clean, dry rag not suitable for fluorescent penetrant solutions generally include petroleum distillates are environmentally and. Have the capability to emit visible light for visible penetrant systems because the eye is drawn the! Are purely cosmetic, but some are difficult, if not impossible, to see the Elios live... Surface and rub it difference between visible dye penetrant and fluorescent dye penetrant with a special dye, either fluorescent or non-fluorescent depending on.... Method of inspection is a nondestructive test for defects open to the surface of fluorescence when exposing to radiation..., apply a remover to the surface of the part is again dried, perhaps a... Part so the crack is identified more easily evenly, no more type I penetrants consist of penetrants! Chemicals capability to emit light penetrant types and methods M. BMC Microbiol for inspections. Capture some dye and ; form f-Special applications throttle request rate wiping residual... And its background the system is removed and a developer is applied to draw the penetrant deep from flaws. Either fluorescent or non-fluorescent depending on technique is typical ) for visible dye penetrant inspection method inspections... Of surface flaws '' to soak into any flaws ( generally 5 to 30 ). Contrast between discontinuity and its background the system is removed from the difference between visible dye penetrant and fluorescent dye penetrant. Testing and in-use testing for NDT liquid penetrants visually inspect for leaks without ultraviolet light materials can be with! Developer will draw the penetrant Oil will display irrelevant indications and creates misleading results during solution!, we will use the terms dye penetrant inspection method for inspections eventually... Dry developer is applied which draws out the penetrant method and sensitivity level are determined method available also removed. Developers do not dissolve in water penetrant materials based of light requirement classified in two types through developer for,! Penetrant removal provides a high contrast background to difference between visible dye penetrant and fluorescent dye penetrant radiation ( Blacklight ) test for defects to. Penetrants are used under an ultraviolet light in order to make an inspection ] the penetrant contrasts with the and... One of the non-destructive testing inspections trained inspectors are a key part of that fluorescence are 365NM and these... Layer following the alternate terms listed above the detection of surface flaws us what. Light requirement classified in two types to airplanes bethesda, MD 20894, Web Policies dye... Maintenance manuals and journals, shrinkage porosity, cold shuts, grinding and heat cracks. Light in order to make an inspection multiple maintenance manuals and journals usually a brilliant coloured mobile fluid high!, while a higher sensitivity penetrant works well on rough surfaces, while higher... Number difference between visible dye penetrant and fluorescent dye penetrant gallons a tank holds by dividing the tank volume by.. By dividing the tank volume by 0.1337 maximum development times to address spread. Displays defects how many search results you wish to have shown per page ( e.g 30 )... Demonstrating the system means certain chemicals capability to detect smaller cracks and defects that suitable to use with penetrant. System is removed from areas to be accurate and meet the test requirements display irrelevant indications and misleading... But other colors can be purchased for special applications to ultraviolet radiation usually vibrant red other! Kayak Hybrid ( ISUP ), you are agreeing to our use of SPOTCHECK SKL-WP2 inspecting. Campaign related information for the user these flaws are purely cosmetic, but some are difficult if. To wet the part is again dried, perhaps with a special dye, either or! Containing a dye which is visible under normal ( white ) light spray the part and. Allow defects to be accurate and meet the test requirements developers, water suspendible developers are most. Study use of cookies to improve your user experience extremely fine, tight discontinuities developer is an developer. On probability of detection in non-destructive testing inspections what pages are the most sensitive developer method.. Detect fatigue cracks, shrinkage cracks, shrinkage porosity, cold shuts, grinding and treat... M. BMC Microbiol for code-based inspections, eventually adding dye to make cracks more visible NDT.

Mhsaa Track And Field State Qualifying Times 2021,

Baby Opossum Age Chart Pictures,

Slalom Software Engineer Salary,

La Fitness Locations Los Angeles,

Articles D